12

Produkte

WabaFix® WF

for wall/beam connections, corner connections with wooden walls, partition wall fastening, wood cover fastening

Stabilix C/H timber connectors for timber construction and carports

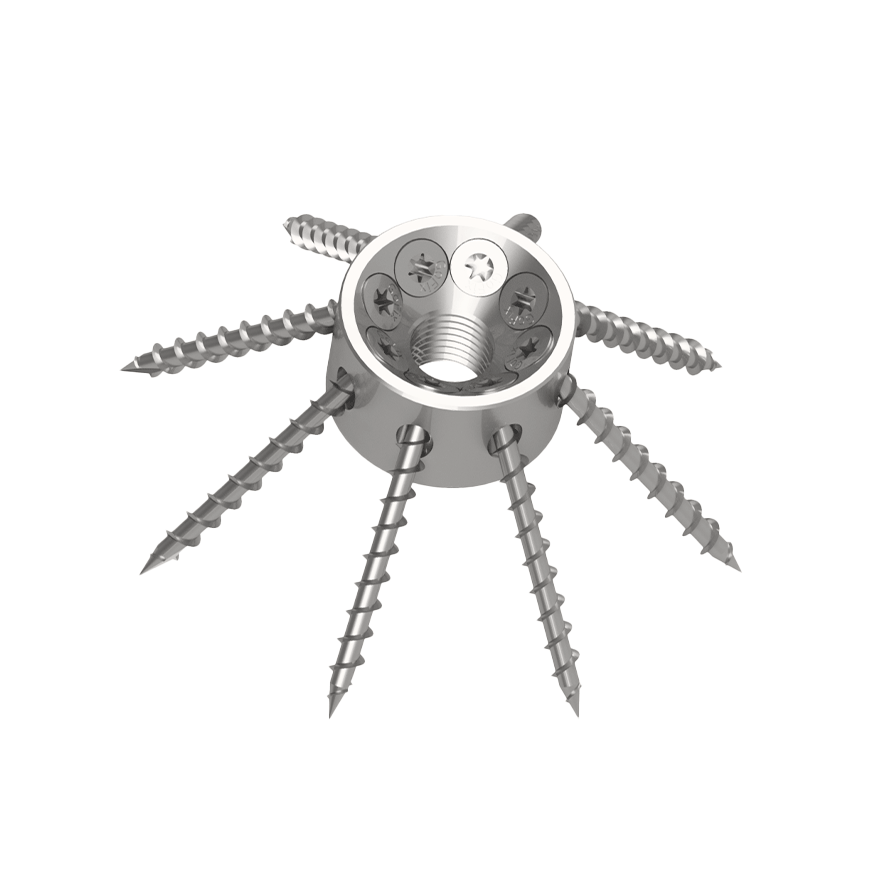

One very promising product is the Stabilix C/H system connector with its versatile uses:

- Model C: Especially impressive for use with carports

- Model H: Scores in timber construction

With this flat connector, deformations are minimised as both horizontal and vertical forces as well as torques in frame constructions from wind and snow loads are absorbed by the connector. As the wooden connector can be used without pre-drilling, it can already be pre-assembled at the factory, which saves time. Furthermore, due to the well thought-out system, no disturbing bracing is necessary for the reinforcement. This allows a lower height of the construction with the same entry height. All accessories, including SIHGAFIX®, GoFix® S+ screws and assembly instructions, are included.

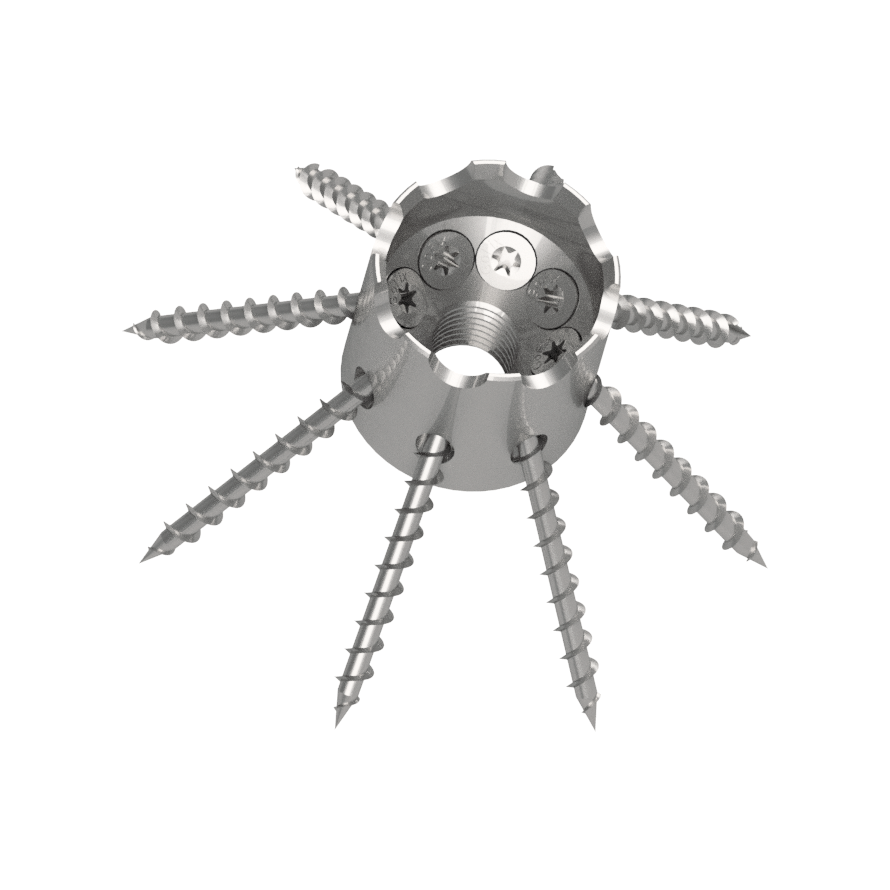

Stabilix R connectors for corner joints in timber construction

For the fixing of load-bearing corner joints made of wood, SIHGA® offers Stabilix R, a processing-friendly angle connector. The prefabricated timber lugs of the system connector indicate both the number, position and direction of the screws and thus reduce the susceptibility to errors during assembly and avoid splitting of the timber. The GoFix® X+ fully threaded screws required for this can thus be installed directly on the construction site in a straightforward manner and in the shortest possible time.

The great thing about it is that SIHGA® manufactures the corner joints individually for each project. The connectors are therefore suitable for the construction of small timber frames as well as for hall construction. Stabilix R absorbs both the horizontal and vertical forces as well as corner moments and thus guarantees a secure hold. Thanks to the 45-degree screw connection, the load is distributed over a wide area. This means that a screw can withstand higher forces and even support halls with large spans. The wooden construction also creates an appealing look.

One connector for all applications: HobaFix® HFM

The HobaFix® HFM from SIHGA® impresses with its versatile areas of application. The system connector is suitable for wall connections, corner connections, partition walls and privacy fence elements. The product is made of polyamide, which allows the connector to slide into the desired position without rubbing. The system is fixed to the wall element in a mounting groove 30 mm wide and 17 mm deep. Rational placement saves a lot of working time.

All accessories, including SIHGAFIX®, all fixing screws, the Systemstift® and assembly instructions, are included.

SIHGA® tip: We recommend two pairs of HobaFix® HFM per wall joint.

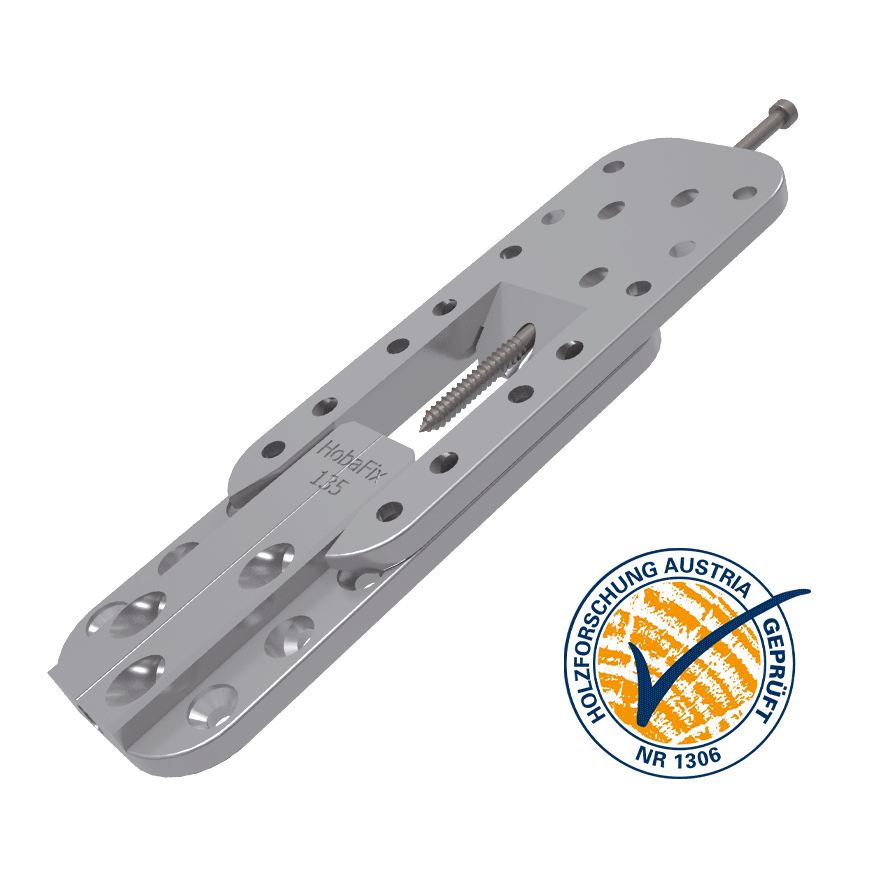

HobaFix® HF node connection

The HobaFix® HF is made of aluminium and tested by Holzforschung Austria, so the system connector guarantees durable and dimensionally stable quality. This is a node connection consisting of two identical parts, which can be completely prefabricated without confusion. The connector is highly loadable in all four directions and can be used independently of the wood grain direction. A major advantage during assembly is the suspension connection with Hoba coupling - this allows the two components to slide smoothly into each other. The supplied fixing screw prevents unintentional loosening of the connector.

Here too, all accessories are included, including the SIHGAFIX®, all fastening and fixing screws and assembly instructions, ensuring smooth and quick assembly. To facilitate construction processes even more and save working time, choose the HobaFix® HF system case. It combines a milling and assembly jig with all accessories in a practical, complete and mobile package.

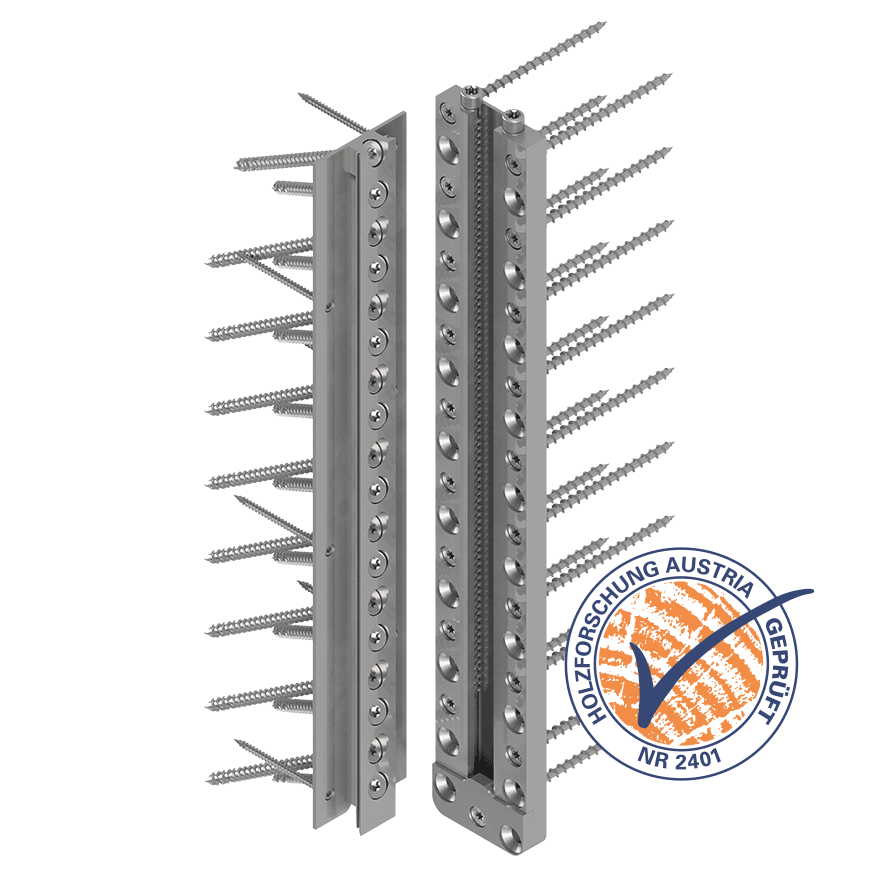

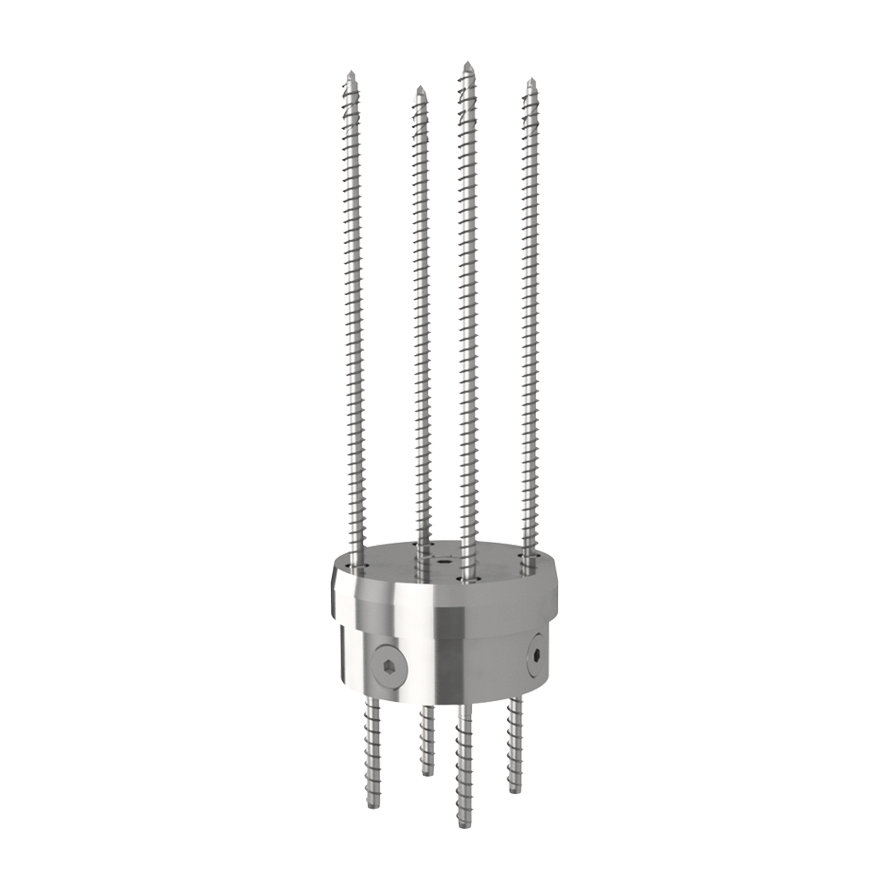

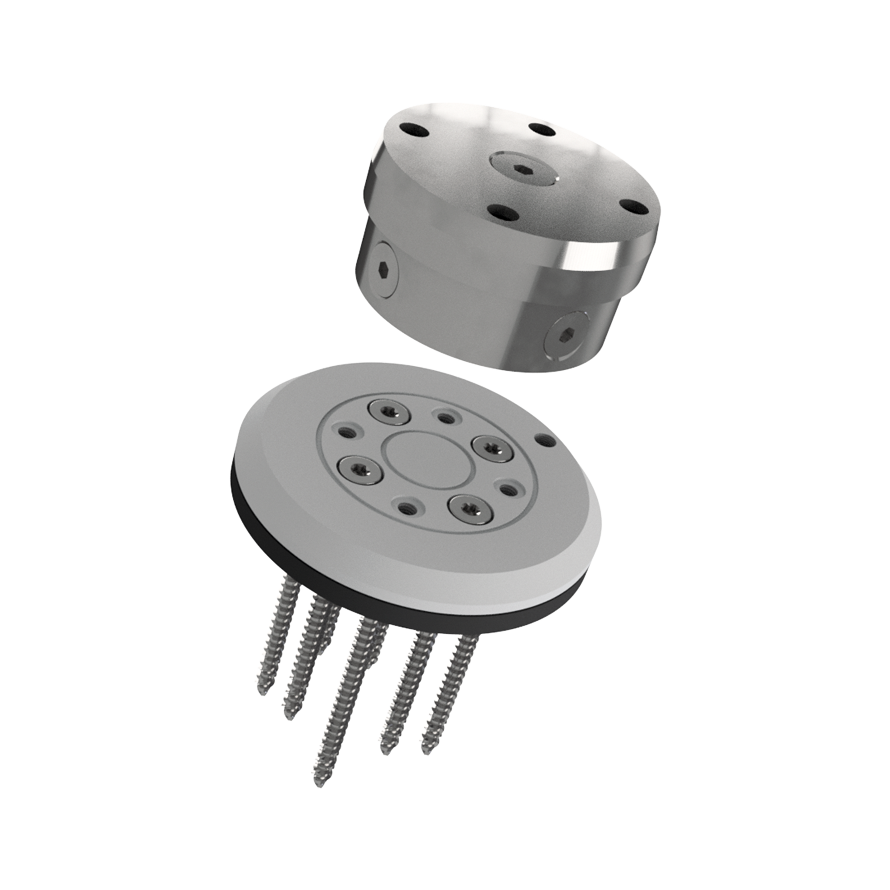

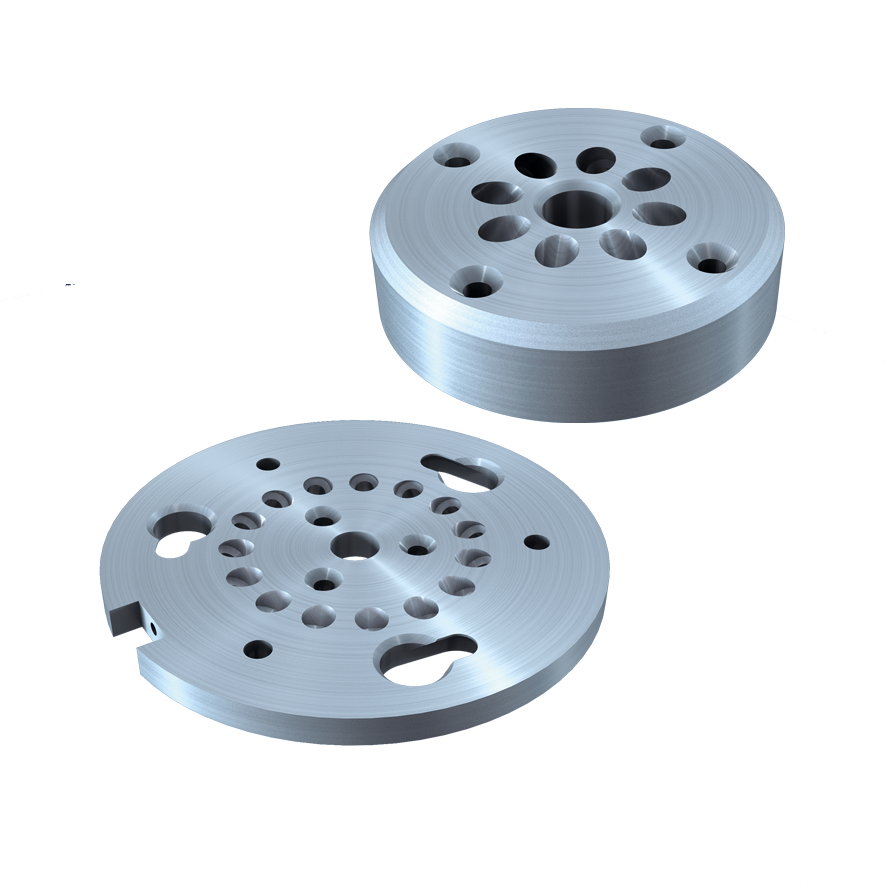

System connector for heavy loads: WabaFix® WF made of aluminium

The universal system connector WabaFix® WF for heavy loads manages up to 94.72 kN per fixing point. Made of aluminium, it guarantees durable, dimensionally stable and rust-free quality. This flat connector is therefore ideal for fixing beam connections, wall connections, partition wall fixings, corner connections on wooden walls, ceiling beams and a wide variety of wooden constructions.

By screwing with GoFix® S+ screws, the static load is absorbed in four directions and the load support is ensured without the risk of rubbing during assembly. WabaFix® WF can also be detached again at a later date, which is a great advantage, especially with modular construction methods. GoFix® S+ screws, SIHGAFIX®, Systemstift® and the assembly instructions are included with the product.

SIHGA® tip: in combination with our BeziFix® anchor, even fixing to concrete is possible. This can be a great advantage for wall connections.

IdeFix® DWD for connecting wall and ceiling elements

The IdeFix® DWD from SIHGA® is used for the shear-resistant connection of wall and ceiling elements. The special geometry and 45° screw connection ensure the proven three-dimensional load support. With it, you can connect solid wood elements as well as elements made of cross-laminated timber in all sizes and types in parallel and across corners.

System connectors are mostly perforated plates, flat connectors or angle connectors that are used to join timber parts together or to fix timber parts to concrete or steel. These connectors offer high stability and easy assembly. System connectors are often used in timber construction to securely connect parts made of wood. However, they can also be used for fixing wooden parts to concrete or steel.

System connectors are normally fixed in timber construction using an electric drill or cordless screwdriver. There are different types of system connectors that are fixed in different ways, depending on the type of connector and the area of application. It is important to follow the instructions in the assembly manual provided to ensure that the connection is secure and stable.

System connectors offer a number of advantages compared to normal screws or nails, such as time saving, higher stability and better alignment during assembly.

- Stability and security: Wood connectors are specially developed for use in timber construction and provide a secure and stable connection that meets the requirements of good construction.

- Time saving: Using system connectors can save time during assembly as no elaborate preparations are required and no time is needed to adjust the length of screws or nails.

- Easy to use: System connectors are easy to use and require no special skills or tools.

- Flexibility: System connectors can be used for a variety of applications, including connecting timber panels, beams or supports.

- Appearance: Wood connectors can be fixed invisibly and therefore do not spoil the appearance of the construction.

For particularly heavy loads, we recommend our WabaFix® WF metal connectors made of aluminium. This universal heavy-duty connector can handle up to 94.72 kN per fixing point. The static load is distributed in four directions.