5

Produkte

Possible applications for post beams, post anchors, support feet and so on

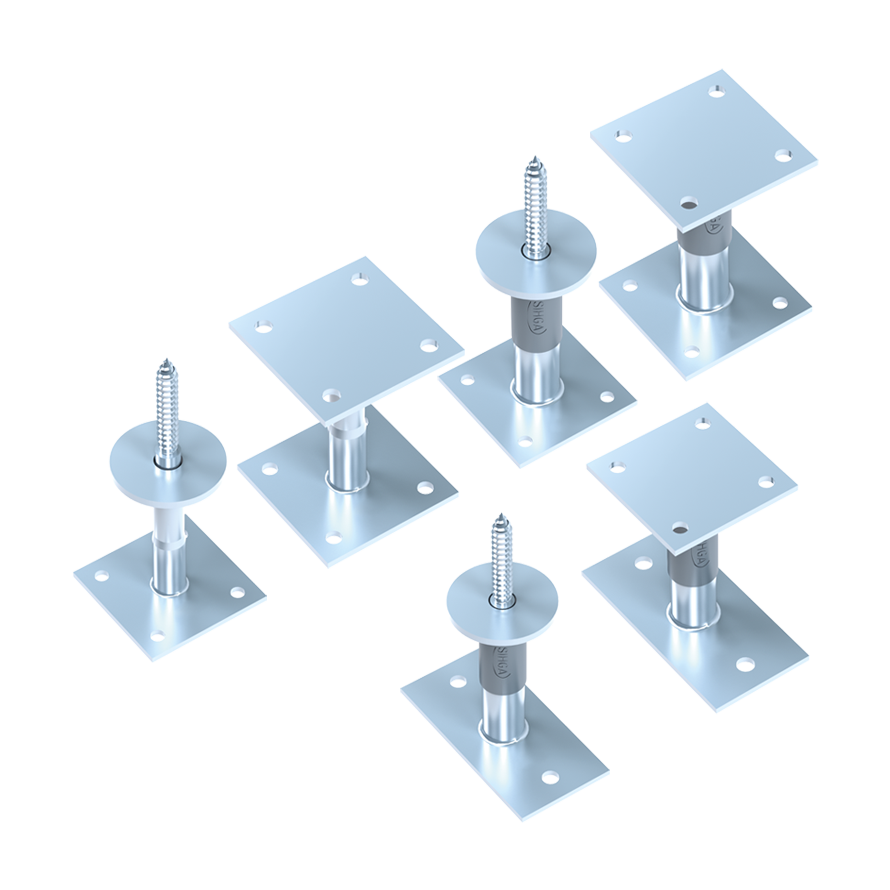

Post beams, post anchors, post shoes, post feet, support shoes or concrete anchors are all forms of a load-bearing element for wooden posts. They are versatile in their use.

Post beams and support feet are often used in timber construction and terrace construction. You can concrete in post beams when building a structure with timber beams, for example, to support heavy timber loads. This makes the beams ideal for canopies, carports, shelters, fences and for anchoring wooden terraces. It also provides the necessary support for aviaries or pergolas. Alternatively, you can also dowel the support feet onto concrete or hammer them into the ground. In short, post beams are used wherever wooden supports are anchored in the ground.

The beams developed by SIHGA® ensure that the structures are particularly stable and also guarantee structural timber protection.

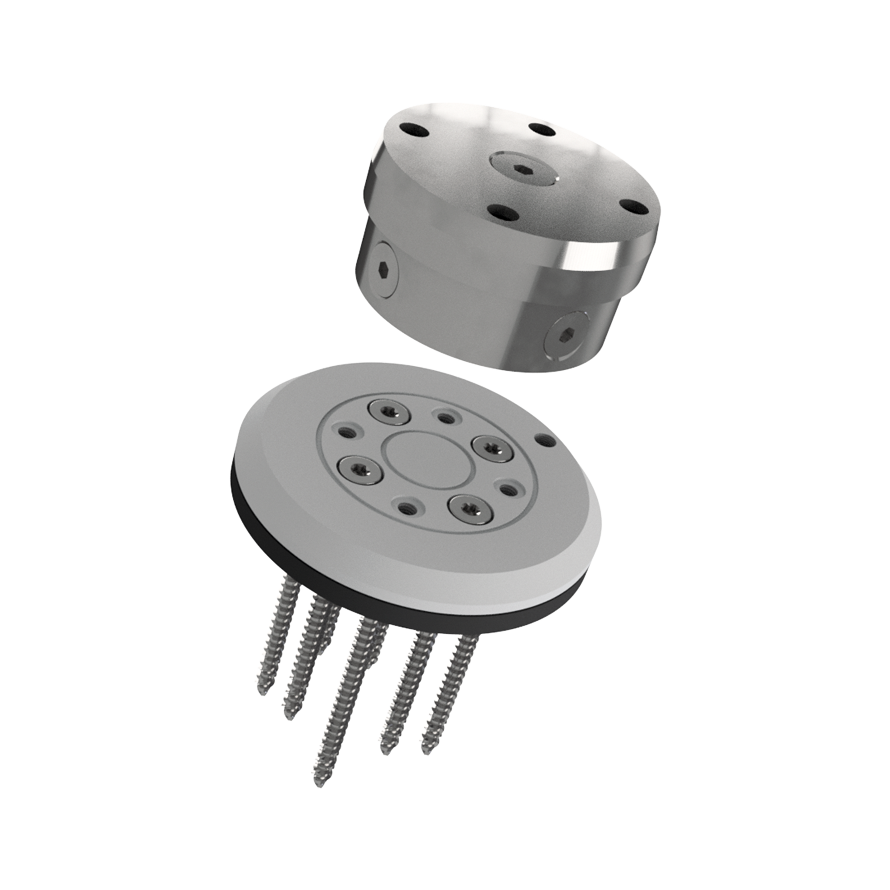

Pfalu® fixings for fence and railing posts

With the Pfalu® post beam, SIHGA® presents a system for fixing fence and railing posts. Thanks to the accessories supplied, the well thought-out beam guarantees quick, easy and, above all, safe assembly of the posts and offers great stability as well as bending stiffness - ideal for fences and privacy screens. The inclination can be adjusted up to 4 degrees in all directions steplessly and in an easily accessible manner.

The required accessories, including SIHGAFIX®, BeziFix® Anchor ZF for wood on concrete or GoFix® S+ for wood on wood, are included. Slotting or milling is not necessary on site, as there are no protruding steel lugs that need to be milled out for fence or balcony elements. There is also no need for screws on the sides that would make it easier for water to get in.

The advantages of SIHGA® Pfalu® at a glance:

- simple installation

- visually appealing

- (re-)adjustable at any time

- no holes

- can be pre-assembled

SIHGA® tip: With BeziFix® SR II the post beam can be fixed to natural stone and with GoFix® S+ screws also to wooden substrates.

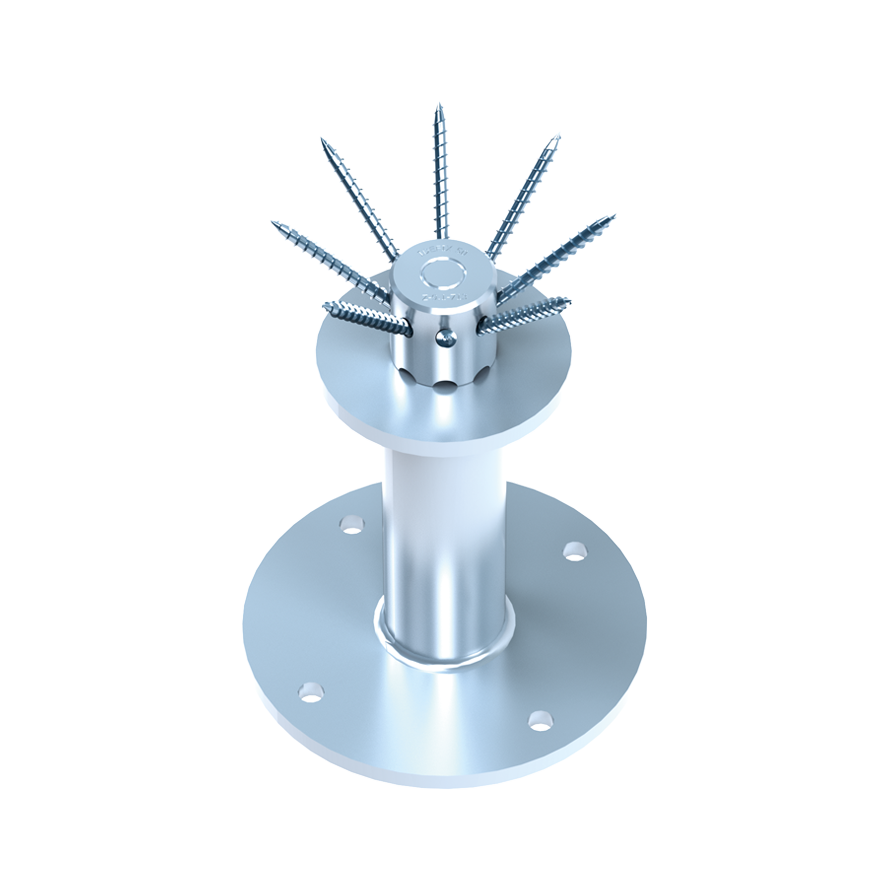

Height-adjustable post beam Herakulix®

The innovative support foot Herakulix® from SIHGA® offers constructions made of wood a high degree of safety. The system consists of a screw-on head plate and a column with base plate. In the XS, M and L versions, the two-part post beam is flexibly adjustable in height and, thanks to the integrated slope compensation, can easily compensate for slight unevenness or slopes in the ground in all directions and in a statically correct way.

Fixing is either with IdeFix® or the fully threaded screw GoFix®. Per fixing point, the post beam absorbs up to 89.09 kN compressive, 29 kN tensile and 3.25 kN shear force.

SIHGA® tip: SIHGA also offers a variant with an inclination adjustability of 45 degrees as well as a version for setting in concrete.

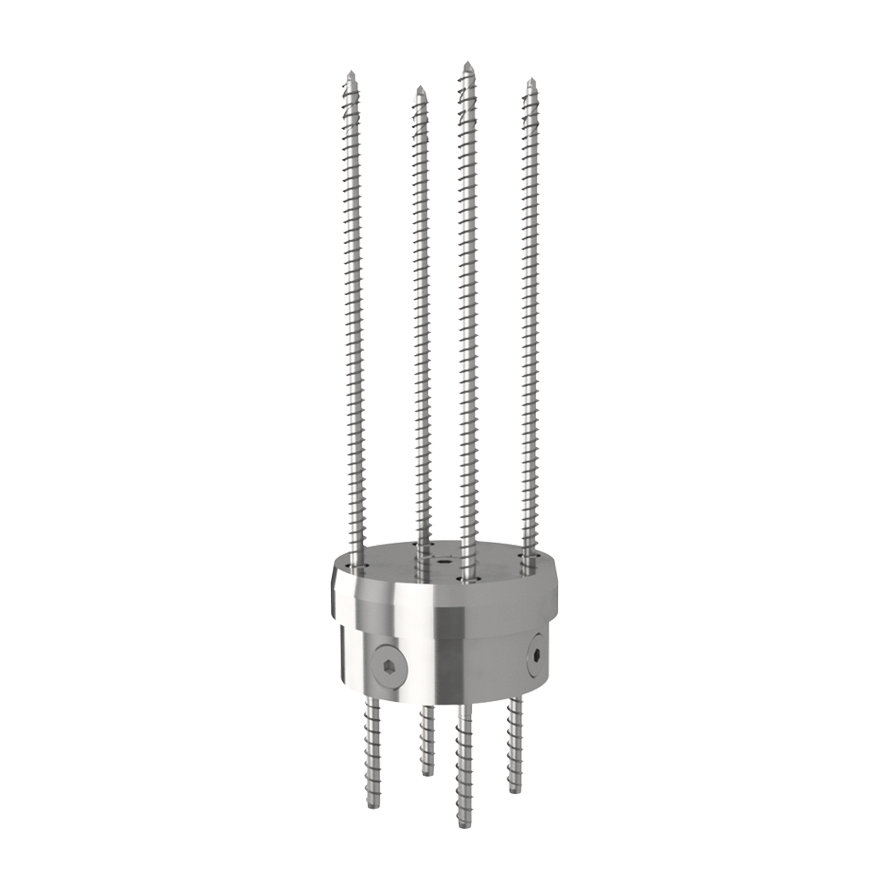

ZaFix® STZ post beam as a permanent & reliable connection

The ZaFix® STZ post beam handles up to 154.5 kN compressive force and 10.57 kN tensile force per fixing point and therefore proves to be a permanently reliable connection in timber construction. The system impresses with its structural wood protection, which keeps surfaces free of damage. Thanks to the thread cover provided by a stainless steel cover sleeve, the carrier offers high corrosion protection and splash water protection. The support foot is galvanised according to ISO 2081, chrome 6-free and has a paintable surface with "self-healing effect" in case of damage to the protective layer. The 300 Series is also height-adjustable even when installed and can be subsequently adjusted at any time.

Post beams are used to fix posts made of wood or steel in the construction of buildings, terraces, carports, fences, pergolas or other similar structures and to avoid direct contact of wood with the substrate. They are an important part of the construction as they absorb the loads and transfer them to the substrate to ensure a safe and stable construction.

Depending on the type of beam and the stability required, post beams can be concreted in, dowelled in or hammered into the ground. There are also several ways to mount the post on the beam. A distinction is made between the drilled, slotted, screwed and externally embracing versions.

When you dig a hole for a post, it should be about twice as wide as the post and at least 80 cm deep to guarantee frost resistance. In elevated areas with heavier frost, a deeper pit of up to 120 centimetres may be useful.

After about 28 days of drying time, the concrete is fully cured. It is important that the fresh concrete is protected from rapid drying and influences such as sun, wind, rain or frost during curing, e.g. by covering it with film.