40

Produkte

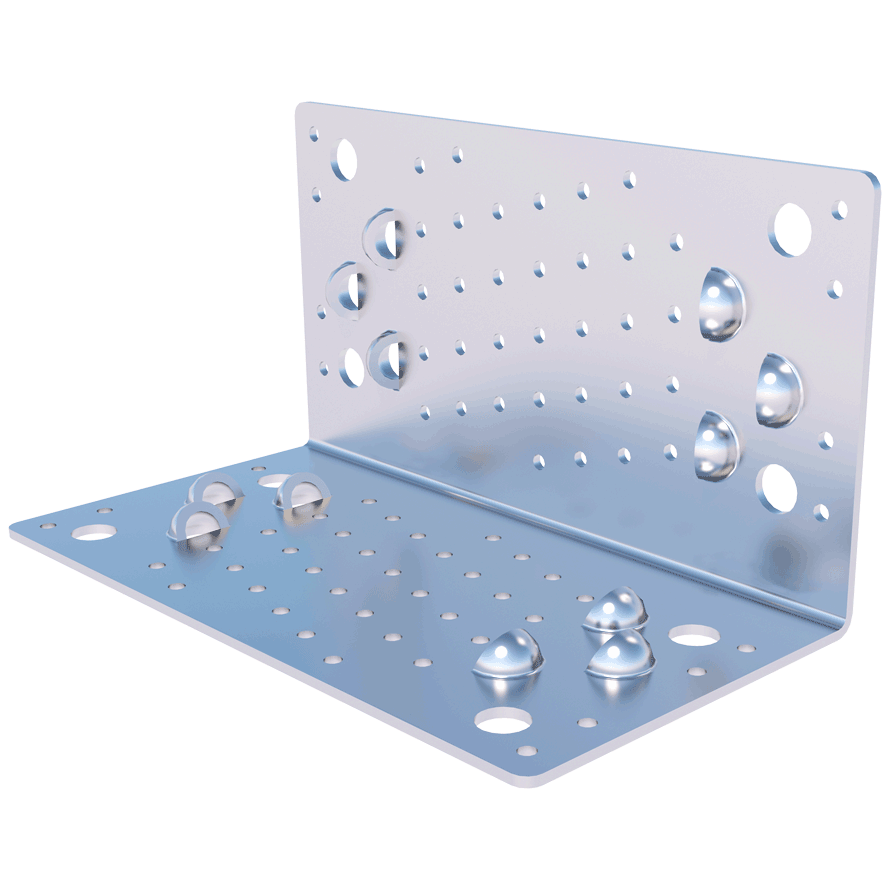

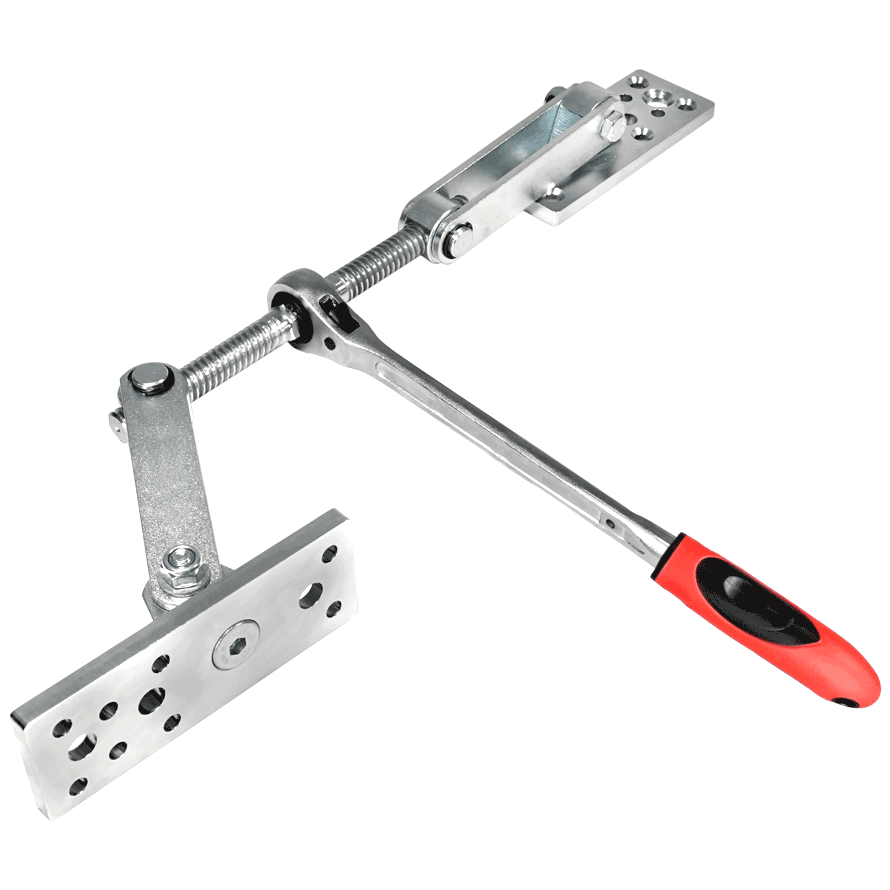

Mass-X® Pull Angle P-HB 340

Steel sheet moulding especially for timber frame construction for the transmission of tensile forces

The basics of CLT

CLT panels are also called cross-laminated timber and consist of several wooden boards that are stacked crosswise in several layers and glued together. Typically, the panels consist of at least three and up to seven layers arranged in an opposite orientation. However, CLT panels can also be made in special configurations, for example with successive layers arranged in the same direction to achieve structural capacities.

CLT panels offer a robust and sustainable solution for timber construction and are increasingly being used in various building projects. The thickness of the individual layers of wood varies from 16 mm to 51 mm, while the width is between 60 mm and 300 mm. The size of CLT panels can vary depending on the manufacturer - typical widths are 0.6 m, 1.2 m, 2.4 m and 3 m, and the length can be up to 18 m.

Uses of CLT panels

CLT panels are used in a wide range of construction projects due to their versatile properties and advantages. The use of CLT panels in construction is steadily increasing as they provide a sustainable and durable alternative to conventional building materials and are being used in residential, commercial and public buildings.

Areas of application include the following:

- Walls: CLT panels are ideal for the construction of load-bearing and non-load-bearing interior and exterior walls. The wood in the layers is aligned to the gravity loads so that the vertical load-bearing capacity of the wall is maximised.

- Ceilings & floors: CLT panels can be used as roof and floor elements to create a stable and durable construction. They provide an even distribution of loads and allow for flexible room design.

- Roofs: CLT panels can be used as roof elements to ensure a safe and durable roof construction. They offer a high load-bearing capacity and enable construction to progress rapidly.

- Modular construction: CLT panels enable an efficient and fast modular construction method in which prefabricated modules are assembled on site. This offers advantages in terms of time and cost savings.

Advantages of CLT in timber construction

- Screw connections are possible at any point.

- Time and cost savings due to prefabrication of the elements.

- Building physics properties of the CLT elements enable almost film-free construction.

- CLT has both sound and heat insulating properties.

- A wide range of architectural design options.

- All components of a house (walls, ceilings and roof) can be made of CLT.

- Lower weight compared to concrete and bricks.

- CLT is fully ecologically recyclable - therefore no construction waste when demolishing buildings.

Timber construction connectors from SIHGA® for connecting CLT/cross-laminated timber

SIHGA® offers timber construction connectors especially for the connection of cross-laminated timber. These timber connectors ensure a secure and permanent connection of the timber elements and contribute to the construction's stability and load-bearing capacity. Through innovative technologies and high-quality materials, the connection solutions from SIHGA® ensure simple and efficient assembly.

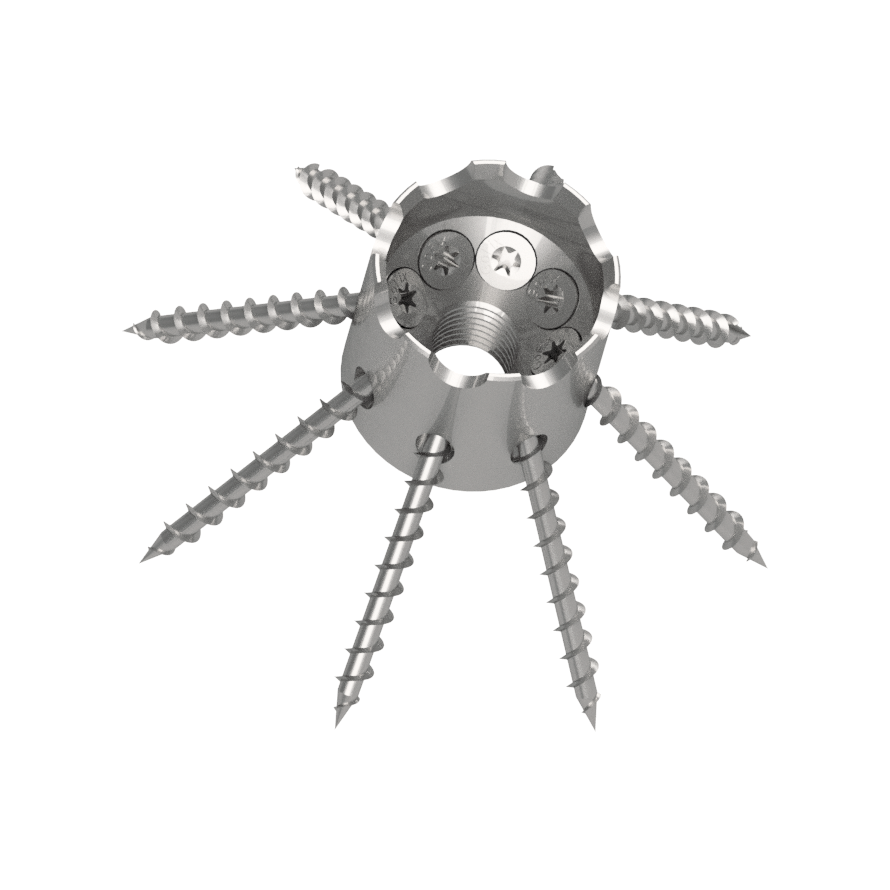

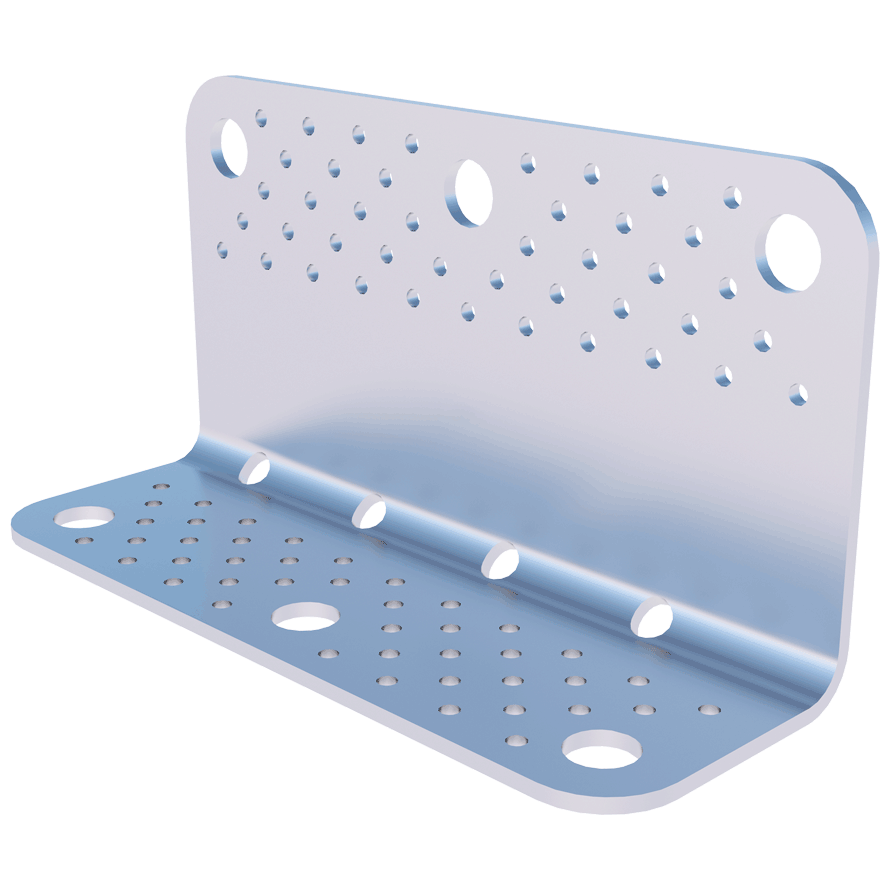

Mass-X® timber construction connectors

The products in the Mass-X® category are ideally suited to use in modern solid wood construction. Due to their solid design, the connectors are able to transmit high forces. Some of the connection solutions can also be combined with IdeFix®, making complex connections possible. The areas of application are versatile - whether it be wood/wood or wood/concrete. Whether angle connectors, panel connectors or brackets developed for modern timber construction, SIHGA® offers everything you need for the secure fastening of your next timber construction project.

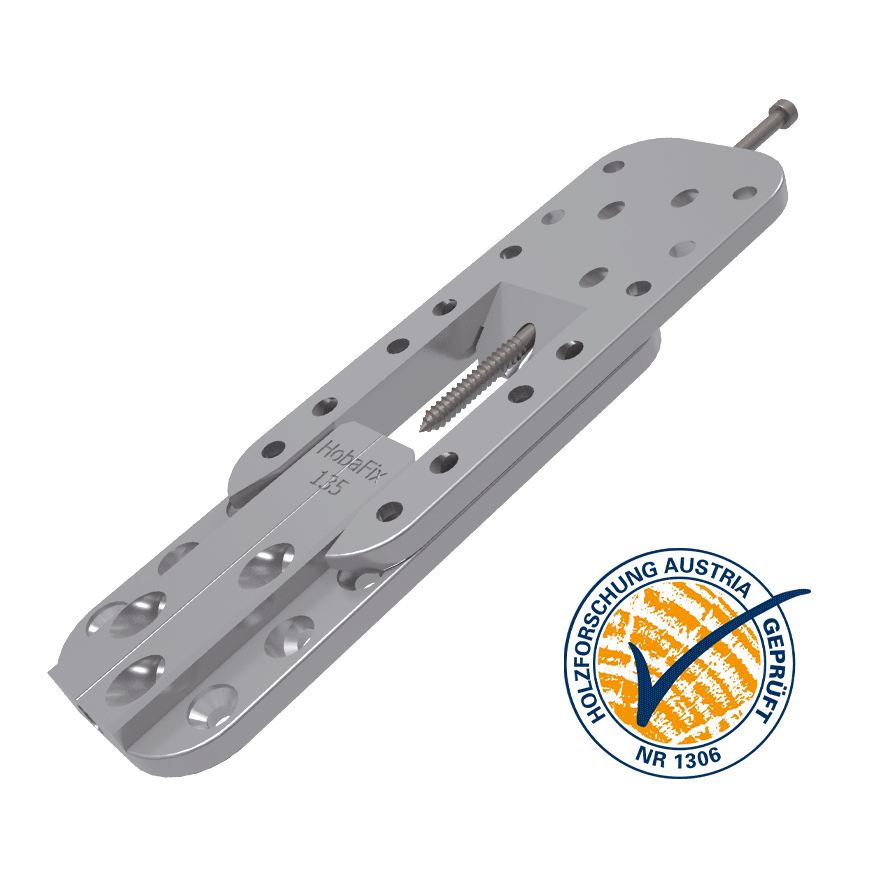

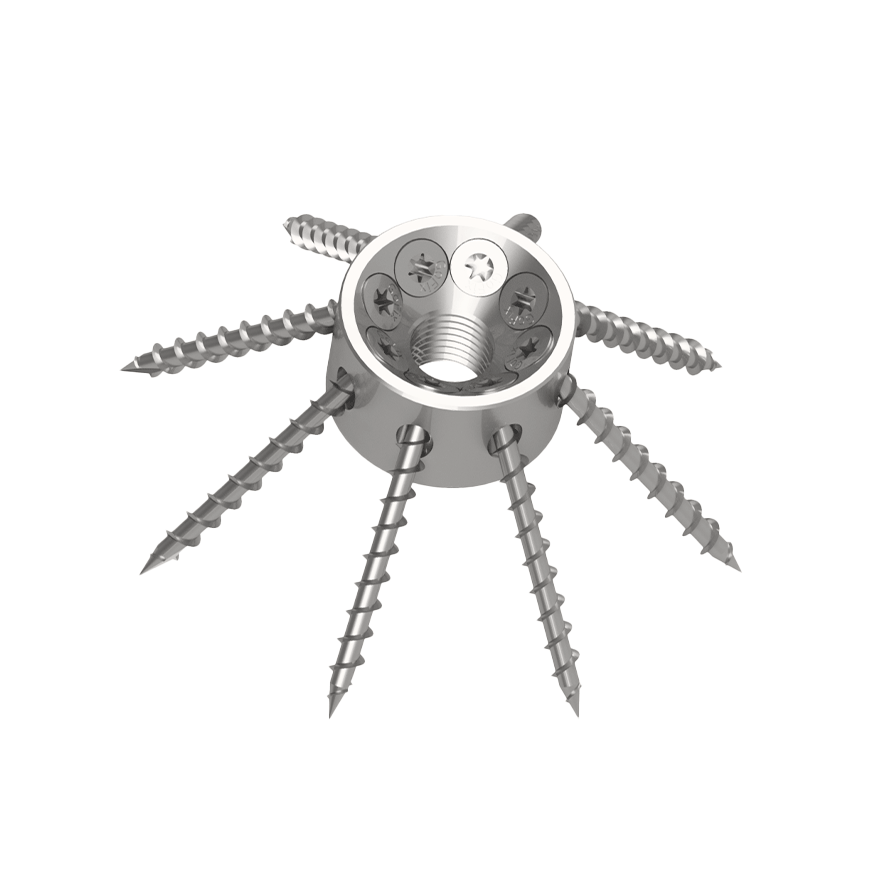

HobaFix® node connection

HobaFix® is a node connection consisting of two identical parts and can be completely prefabricated without confusion. The connector has a high static load capacity, which ensures a permanently secure fastening. The unique suspension connection allows the two components to slide smoothly into each other.IdeFix® DWD connector

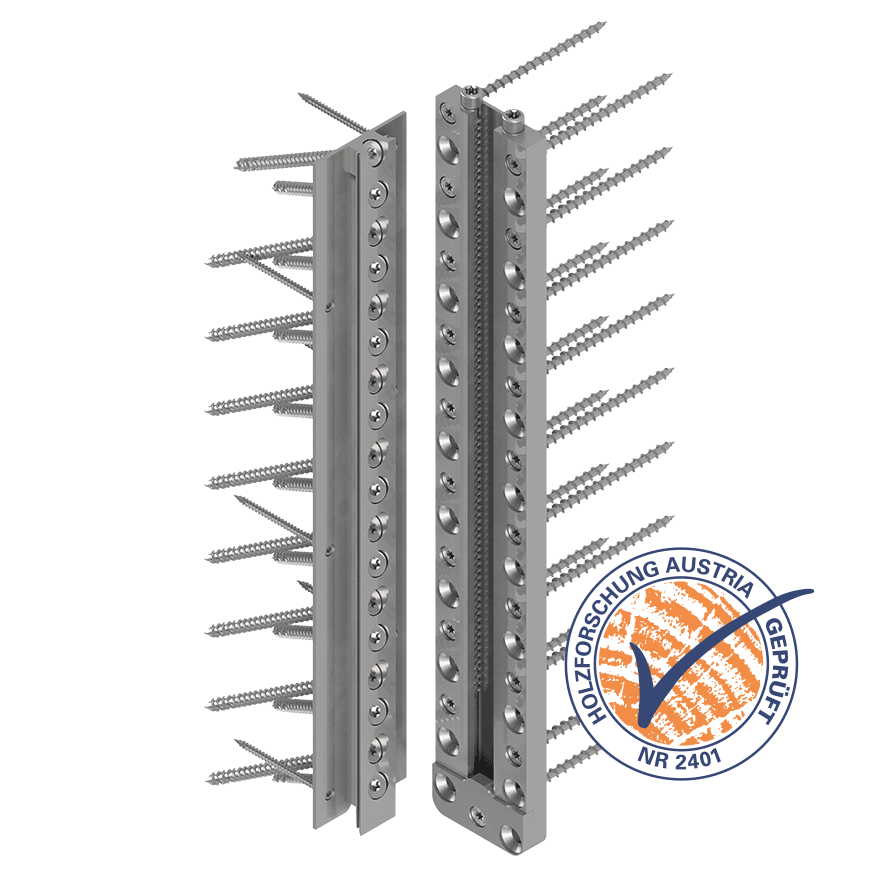

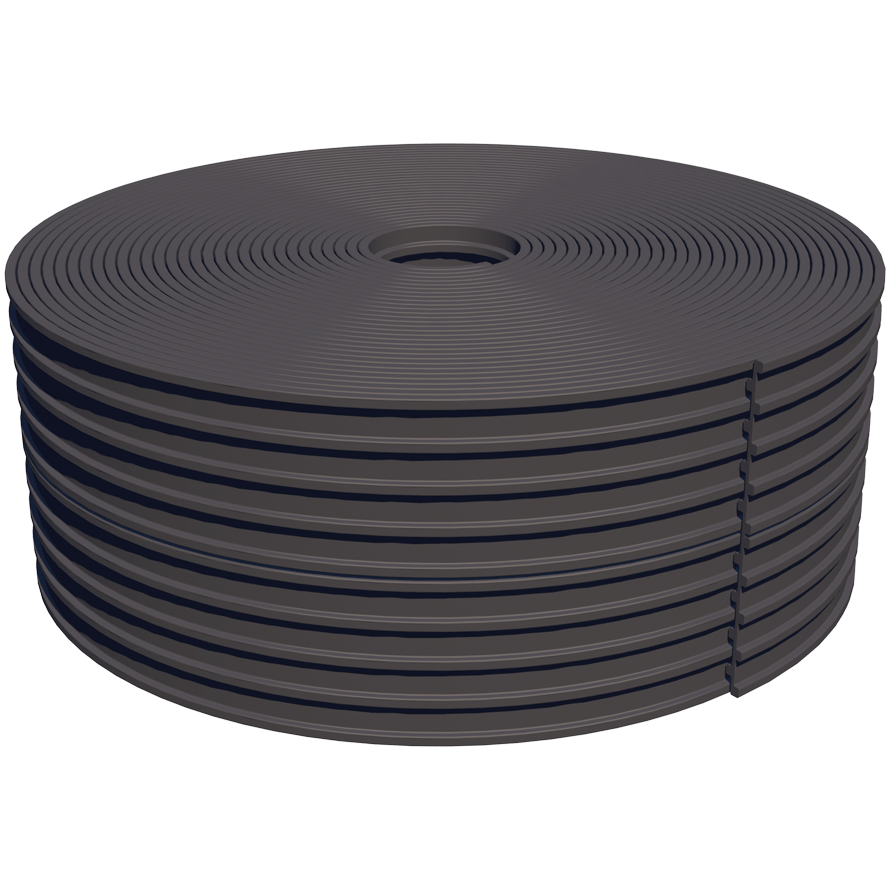

With IdeFix® DWD, SIHGA® offers a reliable and shear-resistant fastener for wooden roof, wall and ceiling elements. With this innovative fastening solution, cross-laminated timber and solid wood components can be securely connected next to each other or across corners. Both planners and contractors can rely on this system, which guarantees maximum efficiency with easy handling.

Structural fasteners for CLT from SIHGA®

In addition to the innovative timber construction connectors, SIHGA® also offers the matching screws. The well thought-out system screws are ideally suited to structural fastening in timber construction.

The BeziFix® anchor is used for dowel-free fastening in concrete and with the various GoFix® wood construction screws, CLT panels can be fastened extremely quickly. Some of the GoFix® screws are also compatible with the Mass-X® timber construction connectors, which allows for simplified assembly. SIHGA® angle fitting screws have been specially designed for connections between sheet steel and wood.

CLT stands for Cross-Laminated Timber. This is a building product made of solid wood, consisting of at least three layers that are glued together crosswise.

Cross-laminated timber is a fully solid timber construction product consisting of several layers. It is used as a solid wood panel in construction.

Modern timber construction methods, such as construction with cross-laminated timber, differ significantly from conventional mineral solid construction methods. Whereas with mineral solid construction most of the work is done on site, with CLT timber construction much of the work is prepared in the factory and later only assembled on site. The prefabrication of the components results in significant time savings. In the joinery centres, all the necessary work is carried out that is difficult to implement on the construction site.

The usual joinery work includes cutting out windows and doors, cutting bevels, cutting to size and notching as well as milling rebate systems and special geometries for special connectors. Care is taken to ensure that all components are matched to each other to the millimetre in order to avoid problems during final assembly on the construction site.