The role of CLT fastening technology in multi-storey timber construction

The various techniques and challenges of CLT fastening.

Multi-storey timber construction is becoming increasingly popular worldwide, not least due to its sustainability, aesthetic benefits and the possibility of reducing the carbon footprint in the construction industry. Cross-laminated timber (CLT) plays a central role in this development. CLT offers high strength and stability, making it a favoured material for multi-storey buildings. A crucial aspect for the safe and effective use of CLT is the fastening technology. In this blog post, we will look at the different techniques and challenges of CLT fastening in multi-storey timber construction.

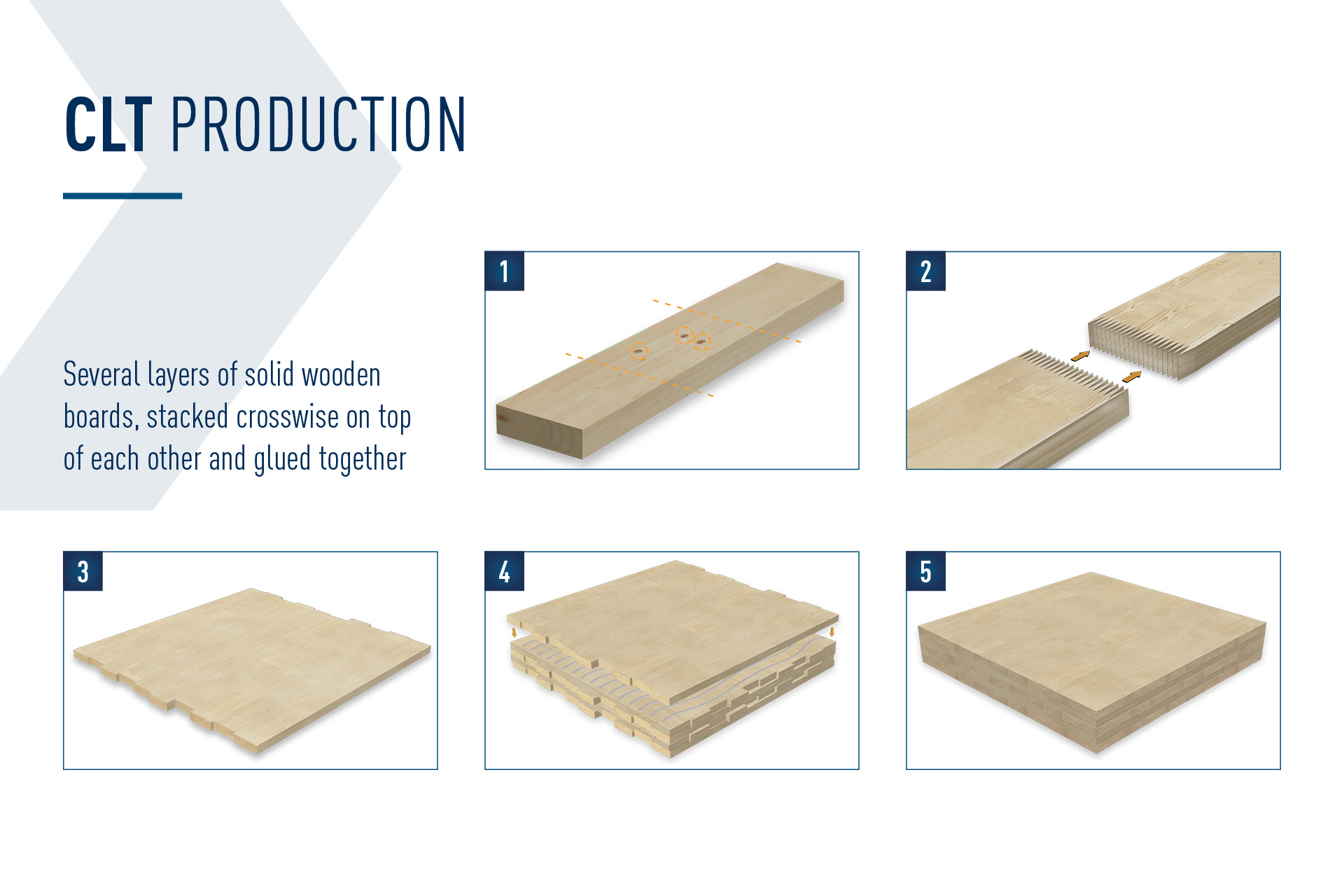

What is CLT?

CLT is a modern timber construction product consisting of multiple layers of solid timber boards stacked crosswise and glued together. This structure gives the material exceptional strength and stability, making it particularly suitable for the construction of multi-storey buildings. CLT panels can be used for walls, ceilings and roofs and offer excellent fire protection and sound insulation properties.

Importance of fastening technology

The correct fastening technology is critical to the structural integrity and safety of CLT buildings. It ensures that the various CLT elements are securely connected to each other and fulfil the structural requirements. This includes the connection of wall-to-wall, wall-to-floor and wall-to-ceiling elements. Incorrect fastening can lead to structural damage and, in the worst case, to failure of the entire structure.

Types of CLT fastening

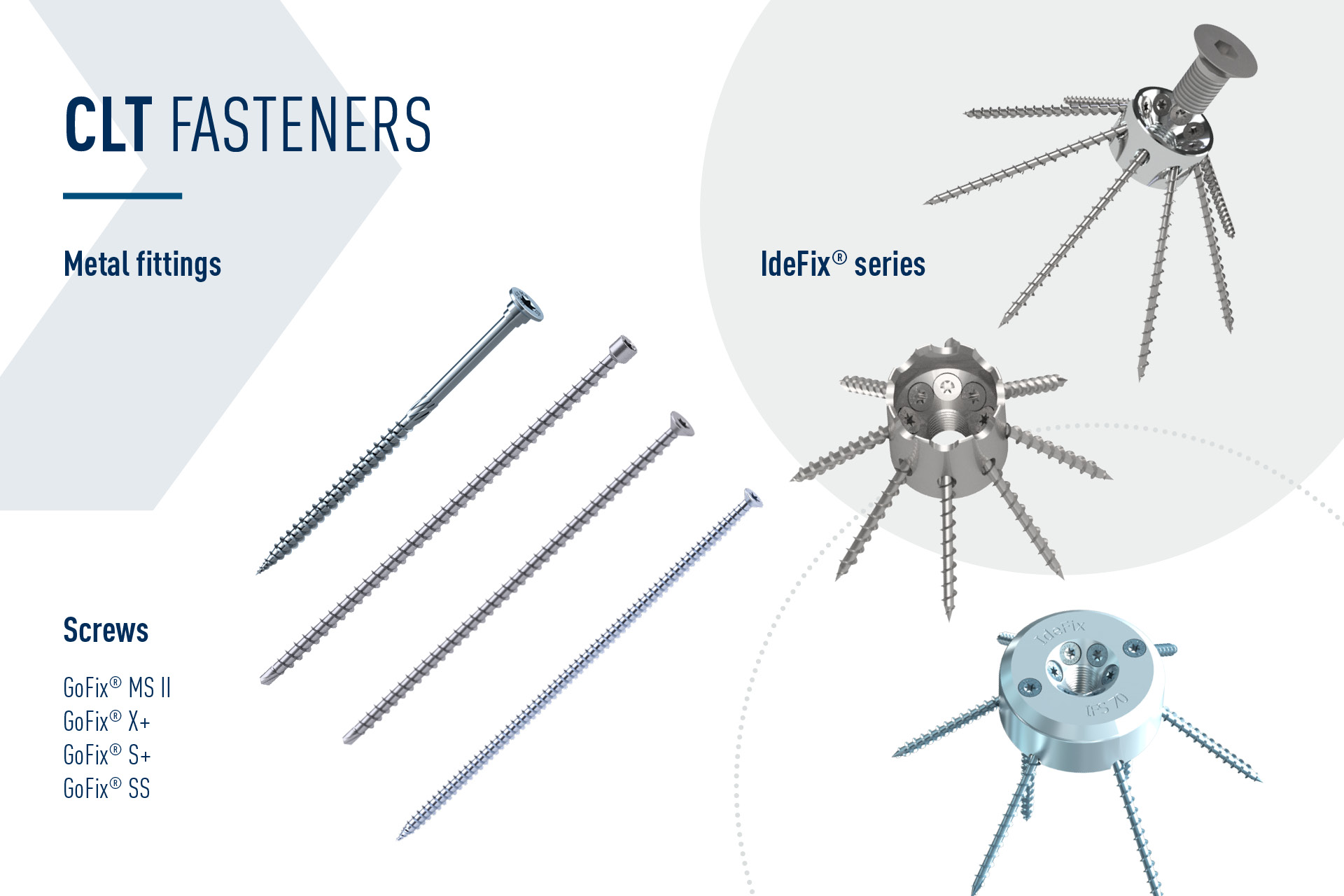

1. Mechanical connections

- Screws and bolts: Specialised wood screws and bolts are often used to connect CLT panels together. They offer a high load-bearing capacity and can be easily loosened again if required. SIHGA offers the product groups GoFix® MS II, GoFix® X+ / S+ and GoFix® SS, optimal durable solutions with high performance.

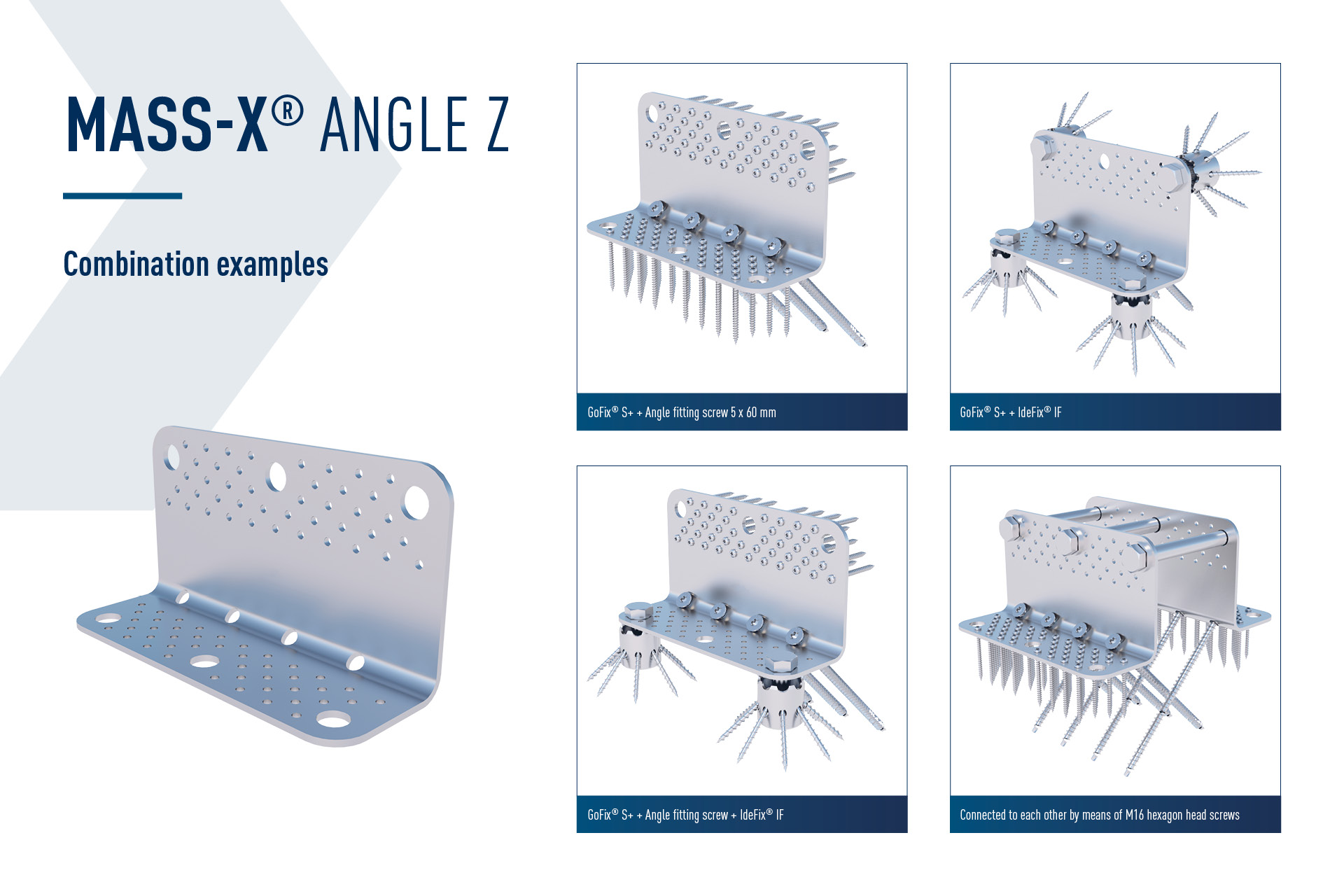

- Bolted/nail-fastened plates: These are often used for load-bearing connections between the individual plate elements. These perforated plates are specially shaped metal plates with holes that enable quick and easy connections. SIHGA offers suitable solutions in the Mass-X® series, as well as from the IdeFix® series.

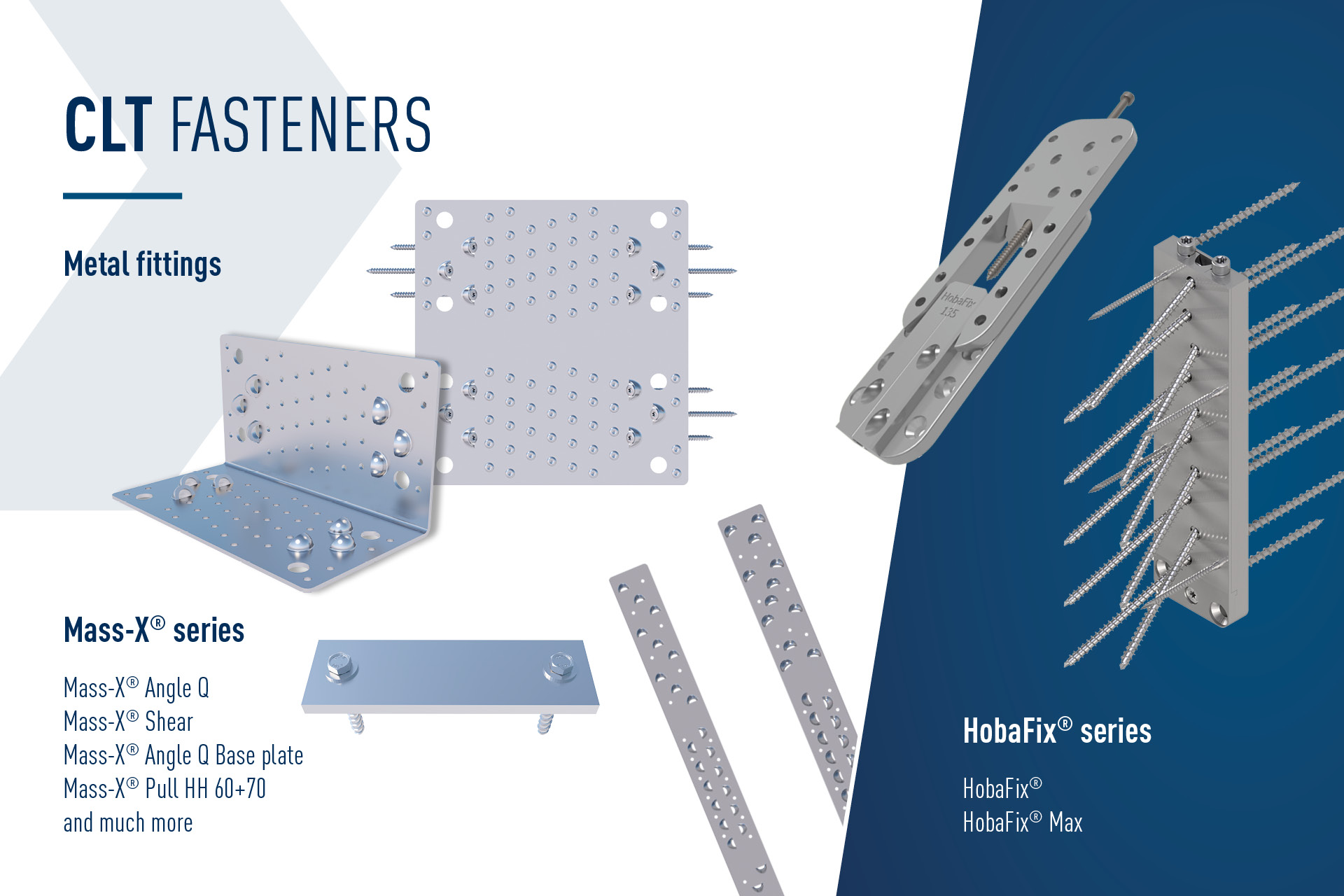

2. Metal fittings

- Angle connectors and hook-in connectors: These metal fittings provide additional stability and are particularly useful at connection points that are subject to high loads. SIHGA offers suitable solutions here in the Mass-X® series, as well as in the HobaFix®/HobaFix® Max series.

- Tension rods and shear systems: These are used to absorb tensile or shear forces and stabilise the structure against horizontal and vertical forces. SIHGA offers suitable solutions in the Mass-X® series.

3. Adhesive bonds

- Structural adhesive: In some cases, CLT elements are additionally or exclusively bonded with structural adhesive. This technique offers very high strength and can provide invisible joints that are aesthetically pleasing. However, given the challenges of deconstruction of the individual elements, chemical bonding should be avoided.

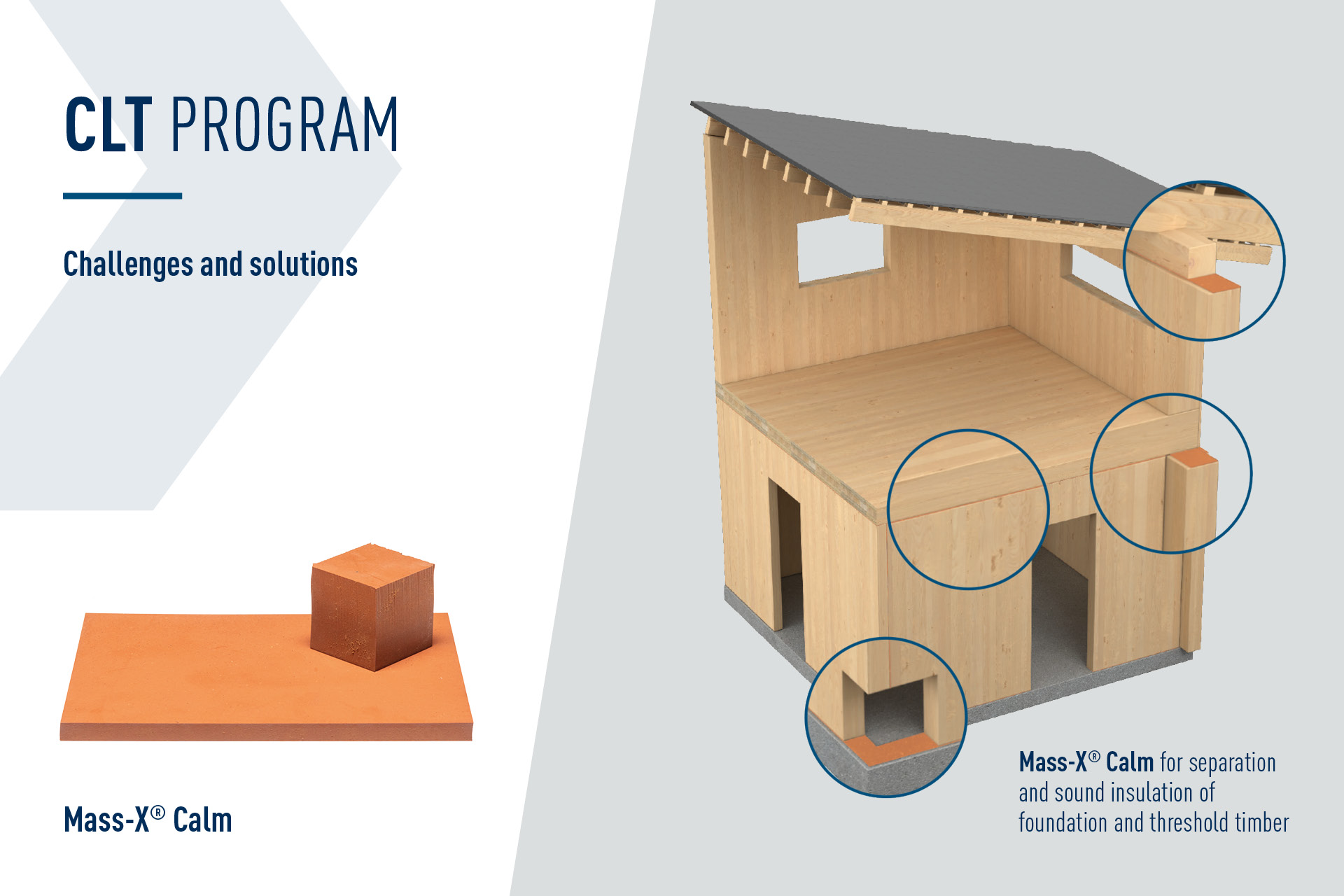

Challenges and solutions

- Shrinkage and swelling behaviour of wood: Wood is a hygroscopic material that reacts to changes in humidity. This can lead to shrinkage and swelling movements that affect the fastenings. Flexible connections and the use of levelling elements can compensate for these movements.

- Fire protection: Despite the good fire resistance of CLT, the fastenings must also be fireproof. Cladding with fire-resistant materials and the use of non-combustible fittings are important measures here if the fire protection requirements need to be higher.

- Sound insulation: To ensure good sound insulation, the connections must be designed in such a way that they do not form sound bridges. Special sound-decoupled connections and sealing materials help to improve sound insulation. SIHGA offers suitable solutions in the Mass-X® Calm series.

Case studies and practical applications

In practice, various techniques and products that have been specially developed for CLT fastening have proven their worth. Examples include projects such as the HoHo Vienna, one of the tallest timber skyscrapers in the world, or the Brock Commons Tallwood House in Vancouver, which impressively demonstrates the possibilities and advantages of CLT construction. These buildings use a combination of mechanical connections and metal fittings to connect the CLT elements securely and efficiently. With the Mass-X® CLT programme from SIHGA, the entire spectrum can be covered.

Conclusion

Fastening technology plays a decisive role in multi-storey timber construction with CLT. Careful planning and the selection of the right fasteners are essential to ensure the structural integrity and safety of CLT buildings. As development and innovation in this field continues, more and more impressive timber construction projects are being realised, demonstrating that CLT is a sustainable and high-performance alternative to conventional building materials.

Our team of timber construction engineers is here to support you right from the planning process, so please get in touch.

1 July 2024