FASTENING OF FAÇADE LOUVERS

Vertical wooden slats are often used in architecture to design and structure buildings. Slats in larger dimensions have a considerable weight of up to 400 kg. Anchoring them to the load-bearing wall therefore requires careful consideration, especially as a number of boundary conditions need to be taken into account. With the LamellenFix, SIHGA has now brought a solution onto the market that meets both technical and aesthetic requirements and is also absolutely economical.

The development of the LamellenFix was based on the following considerations:

- concealed fastening behind the wooden slat

- constructive wood protection

- high load-bearing capacity with verified values including approval

- Homogeneous load distribution across all fastening nodes

- simple assembly and disassembly incl. tolerances

- High degree of prefabrication for all substrates (timber, concrete, metal)

- Cost certainty right from the planning phase

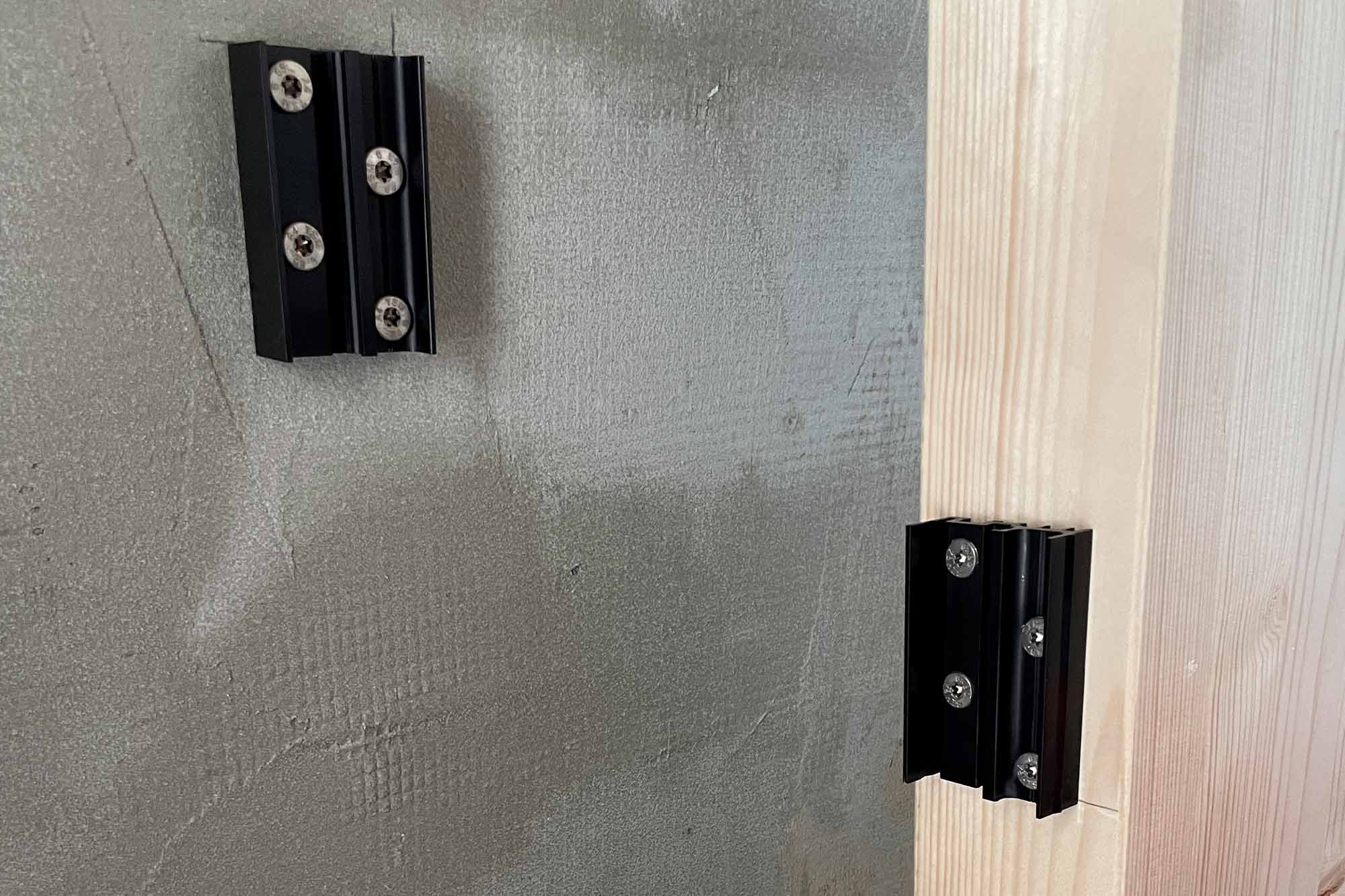

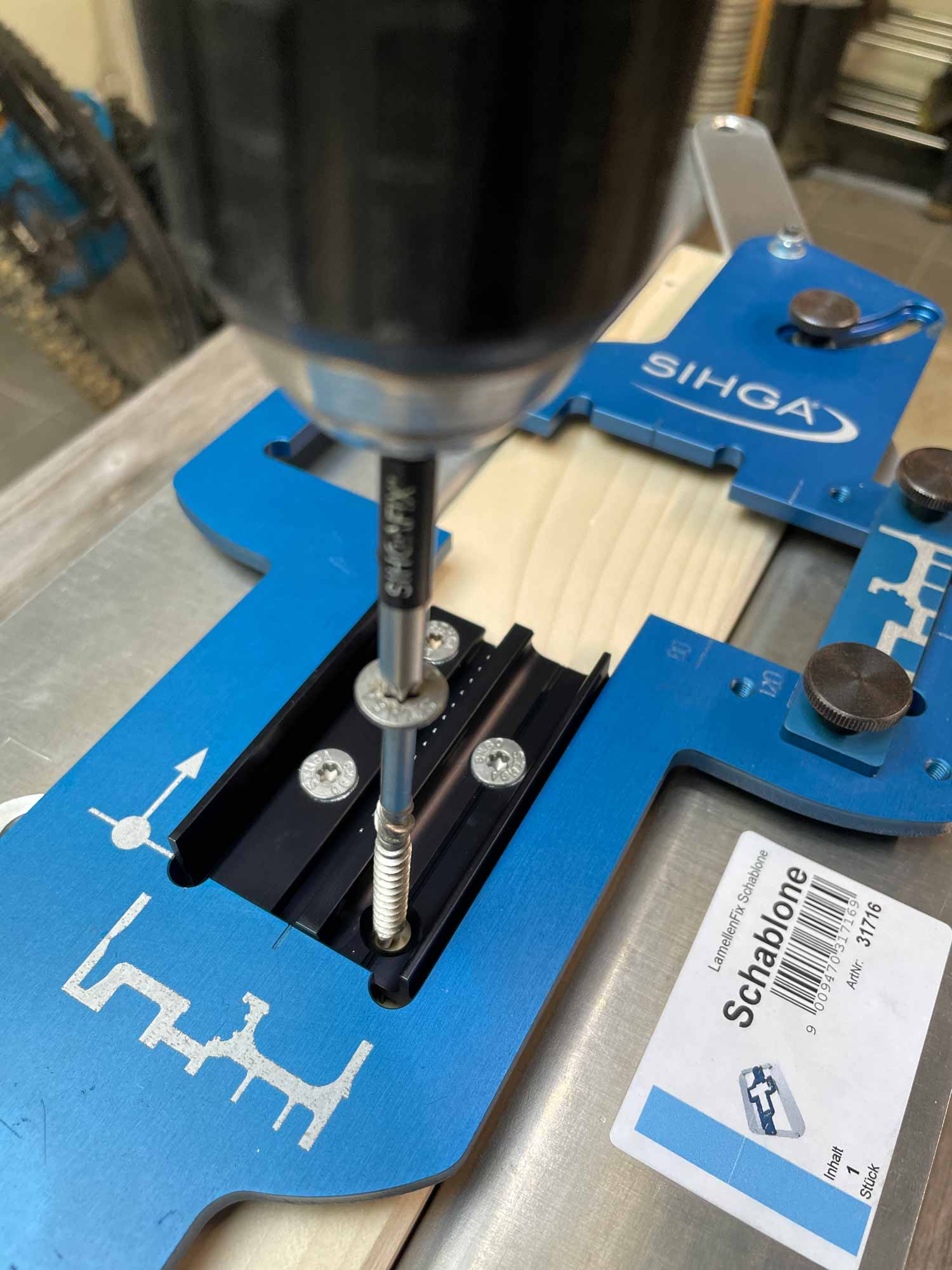

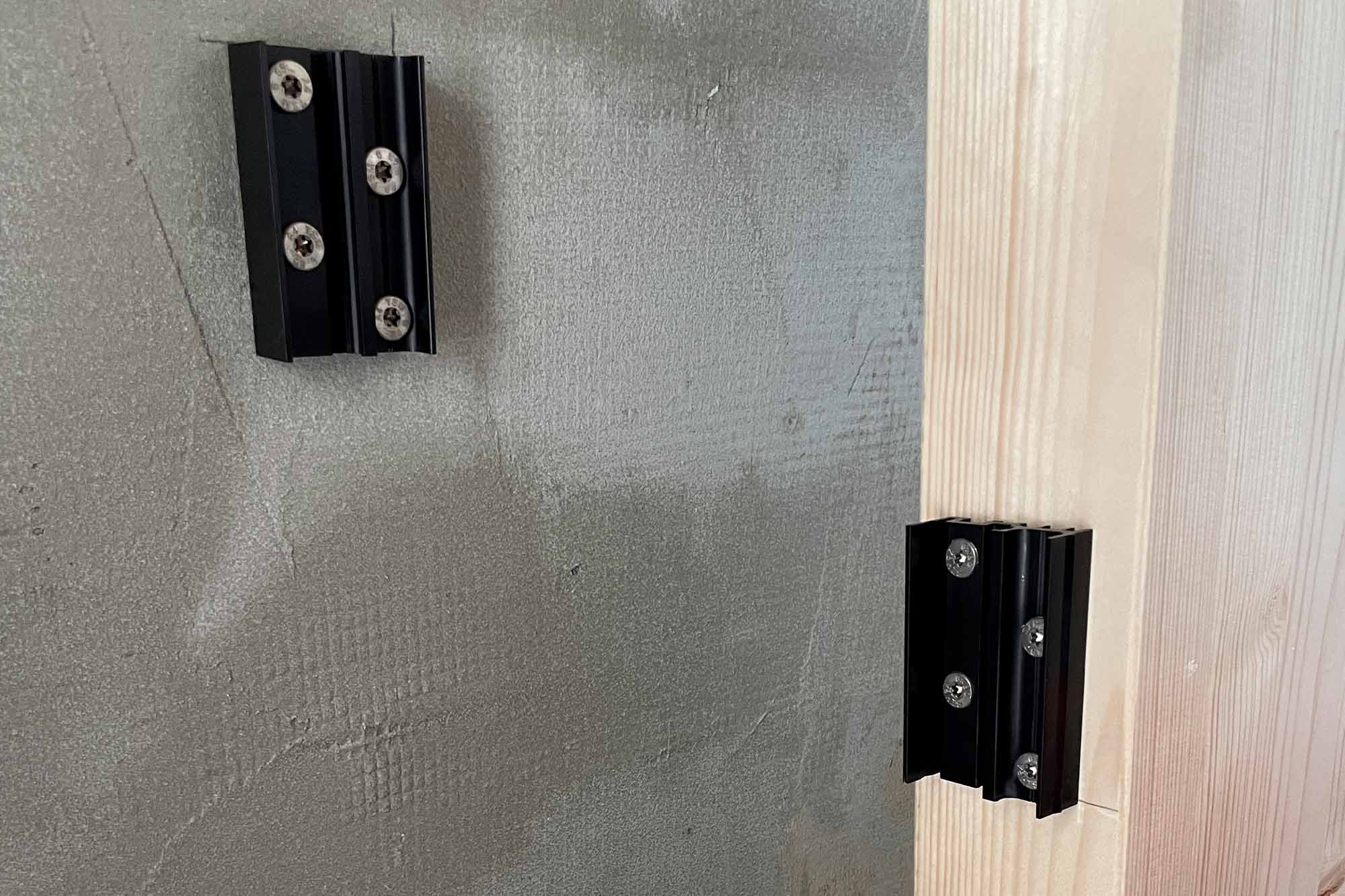

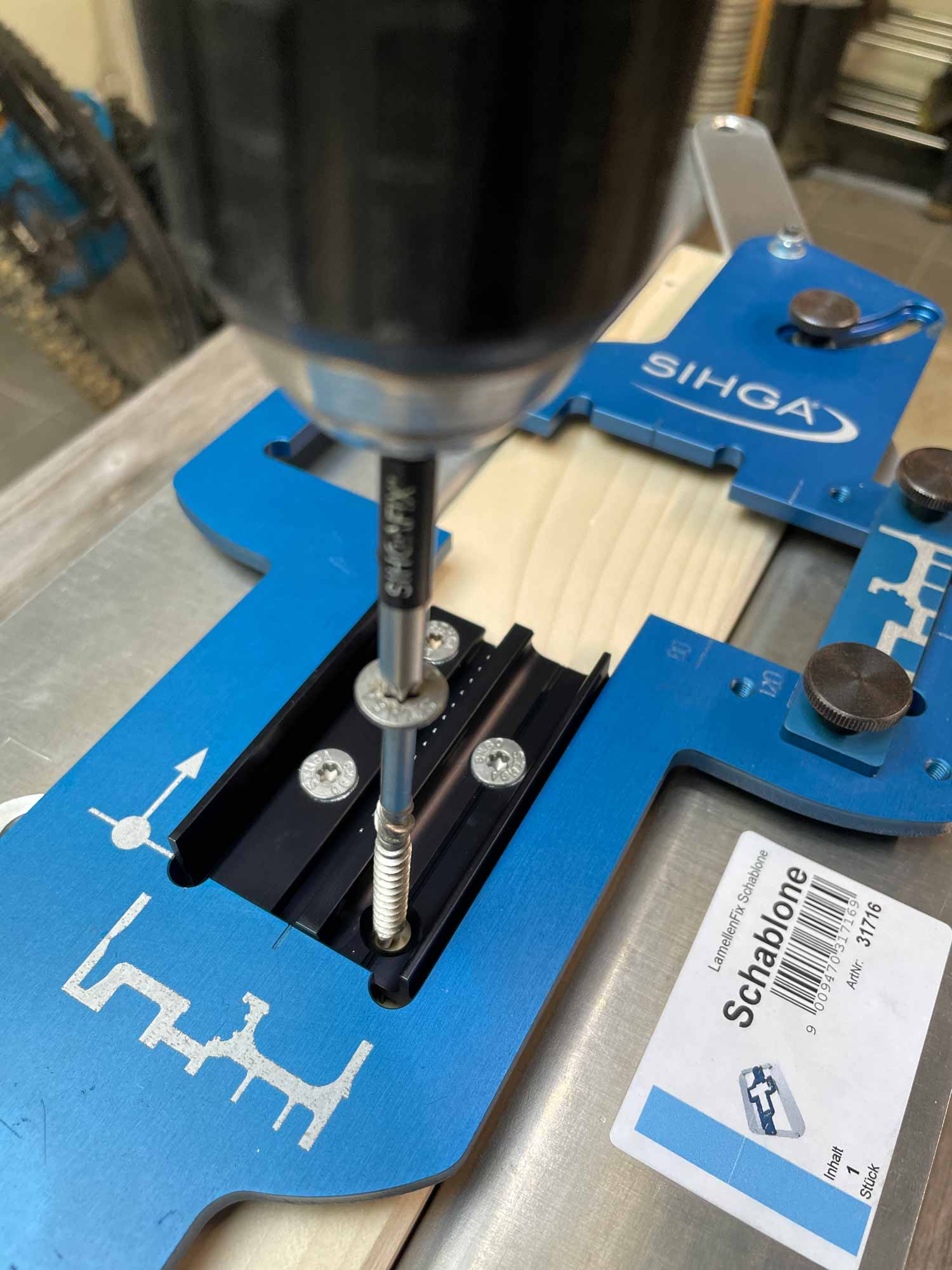

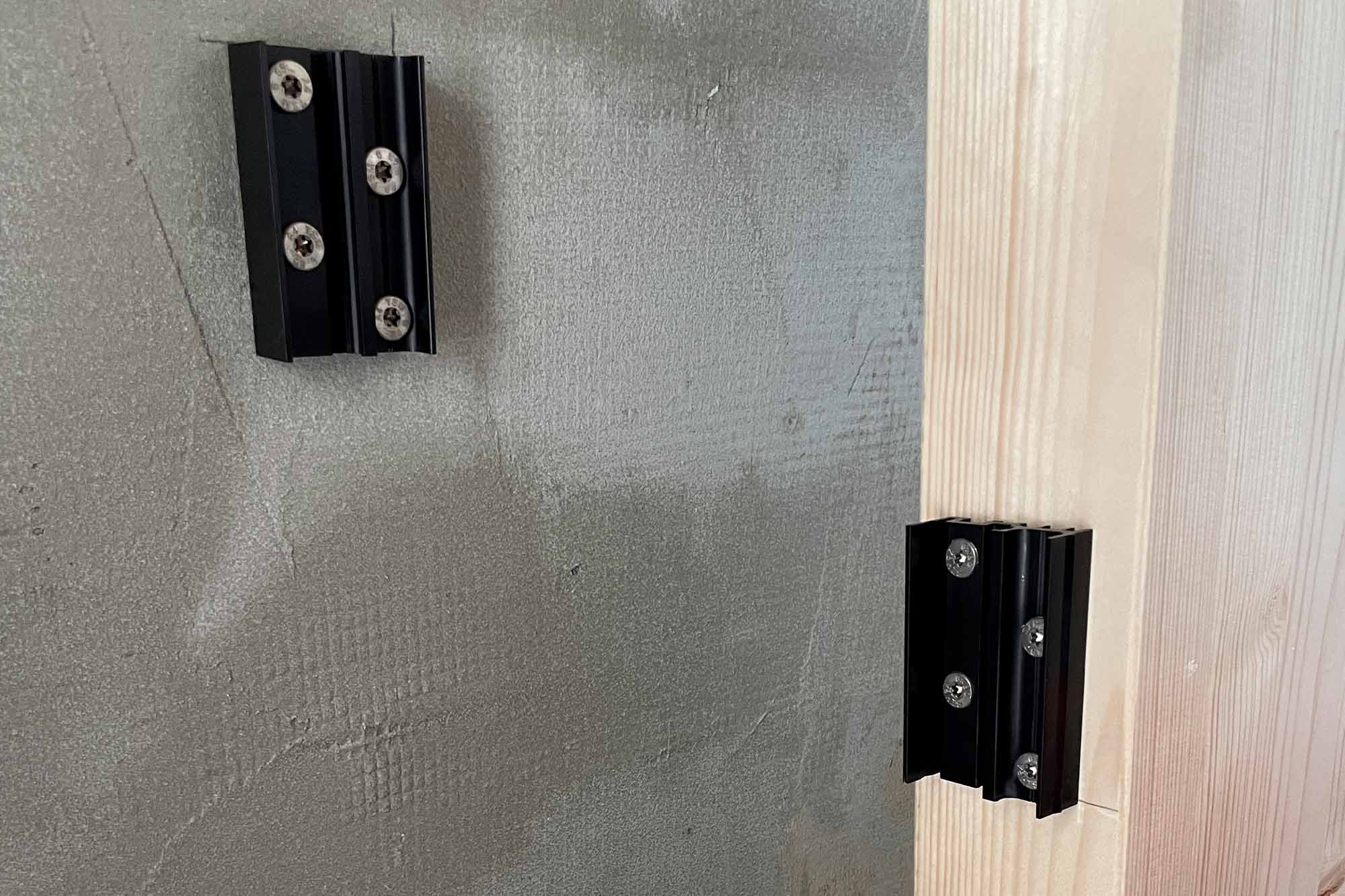

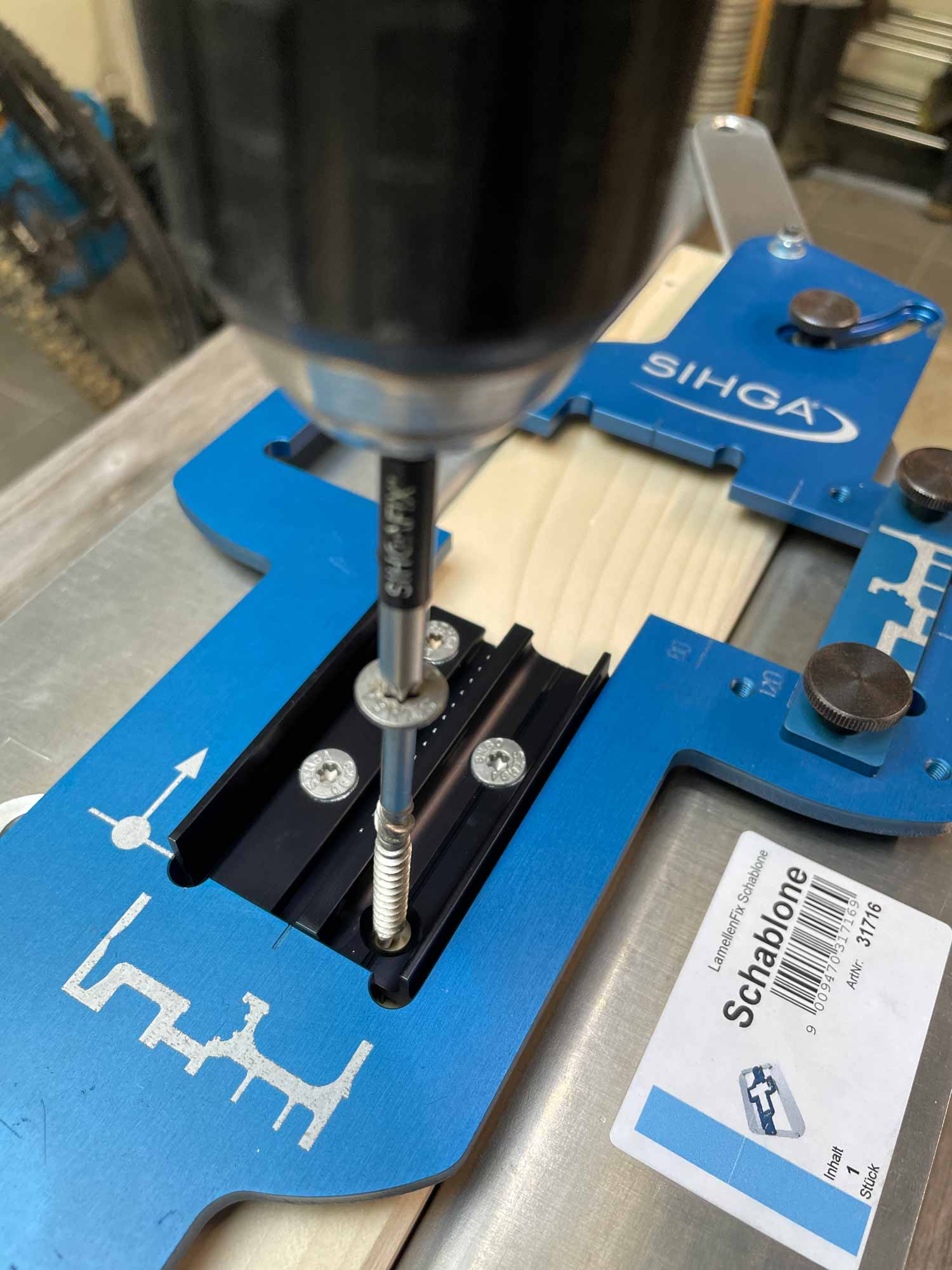

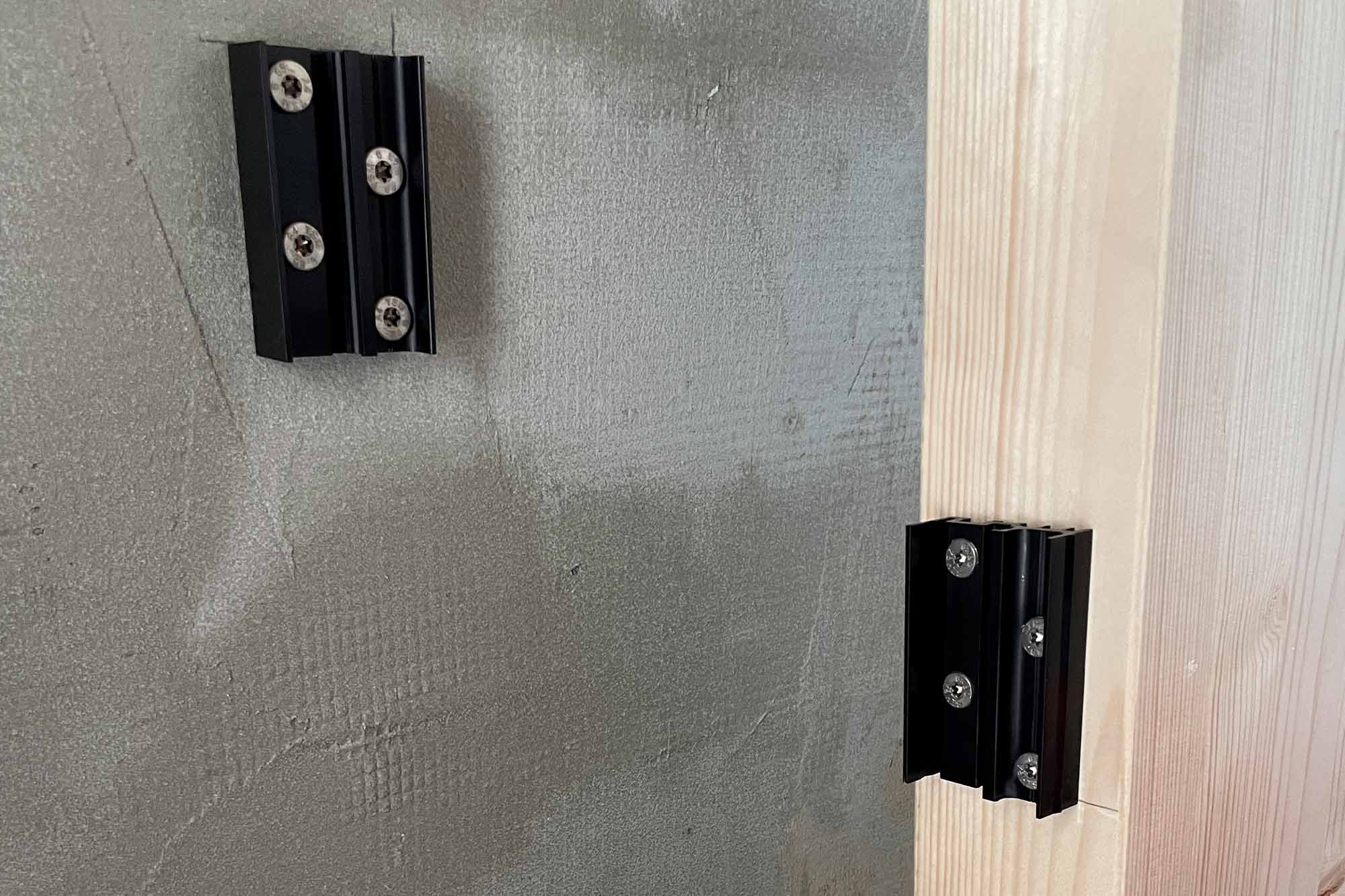

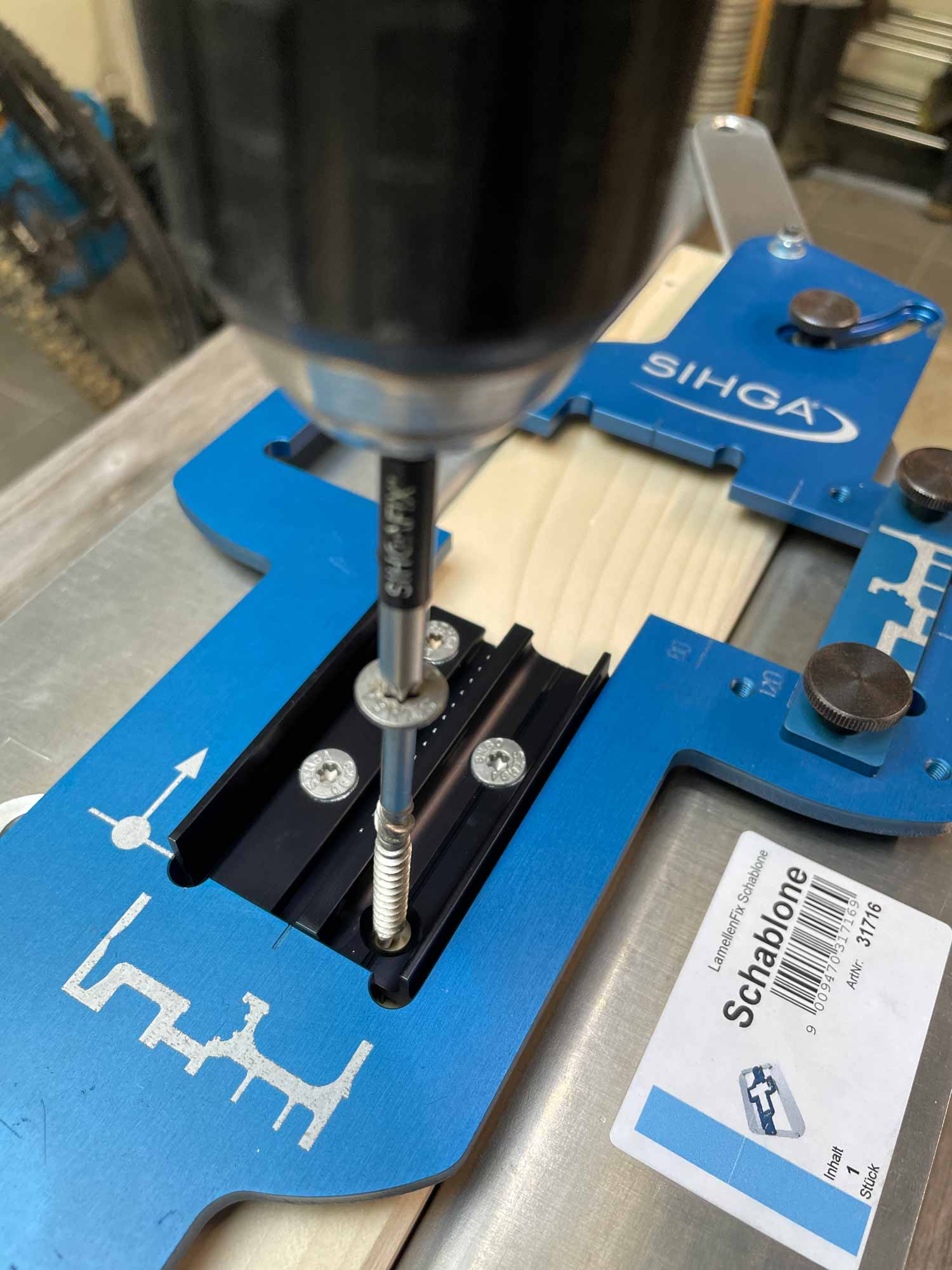

The innovation is based on a node connection made from two identical aluminum shells, which eliminates the risk of confusion. The connector half on the slat side can be precisely pre-assembled on the narrow side of the slat using a specially developed template. The wall-side connector half is installed on site using the stainless steel screws supplied. The system enables screw solutions for any substrate.

The wooden slats are installed by simply clipping the wooden slat onto the connector part on the building side from the front. Finally, a fully threaded locking screw is screwed into the center of the connector from above or below. This creates a force-fit connection between the two connector parts. The system easily accommodates height offsets of up to 8 mm and therefore offers sufficient installation tolerances. As the locking screw is located behind the wooden slat, a special bit is required for this, which SIHGA has in its range.

The special geometry of the connector profile ensures safety and a long service life. Water can drain away quickly and air flows through the connector support. The first project implementations are currently being prepared with architectural firms. Special conditions are available for pilot applications during the market launch phase. Please send inquiries to m.palfi@sihga.com.

The wooden slats are installed by simply clipping the wooden slat onto the connector part on the building side from the front. Finally, a fully threaded locking screw is screwed into the center of the connector from above or below. This creates a force-fit connection between the two connector parts. The system easily accommodates height offsets of up to 8 mm and therefore offers sufficient installation tolerances. As the locking screw is located behind the wooden slat, a special bit is required for this, which SIHGA has in its range.

The special geometry of the connector profile ensures safety and a long service life. Water can drain away quickly and air flows through the connector support. The first project implementations are currently being prepared with architectural firms. Special conditions are available for pilot applications during the market launch phase. Please send inquiries to m.palfi@sihga.com.

30 November 2023