ProziFix® wall anchors from SIHGA®

ProziFix® wall anchors from SIHGA®

ProziFix® wall anchors for safe and easy installation

The anchor is available in a diameter of 50 millimetres and in various lengths from 190 to 400 millimetres. All materials required for installation are supplied by SIHGA®.

Advantages of the ProziFix® wall anchor in timber construction

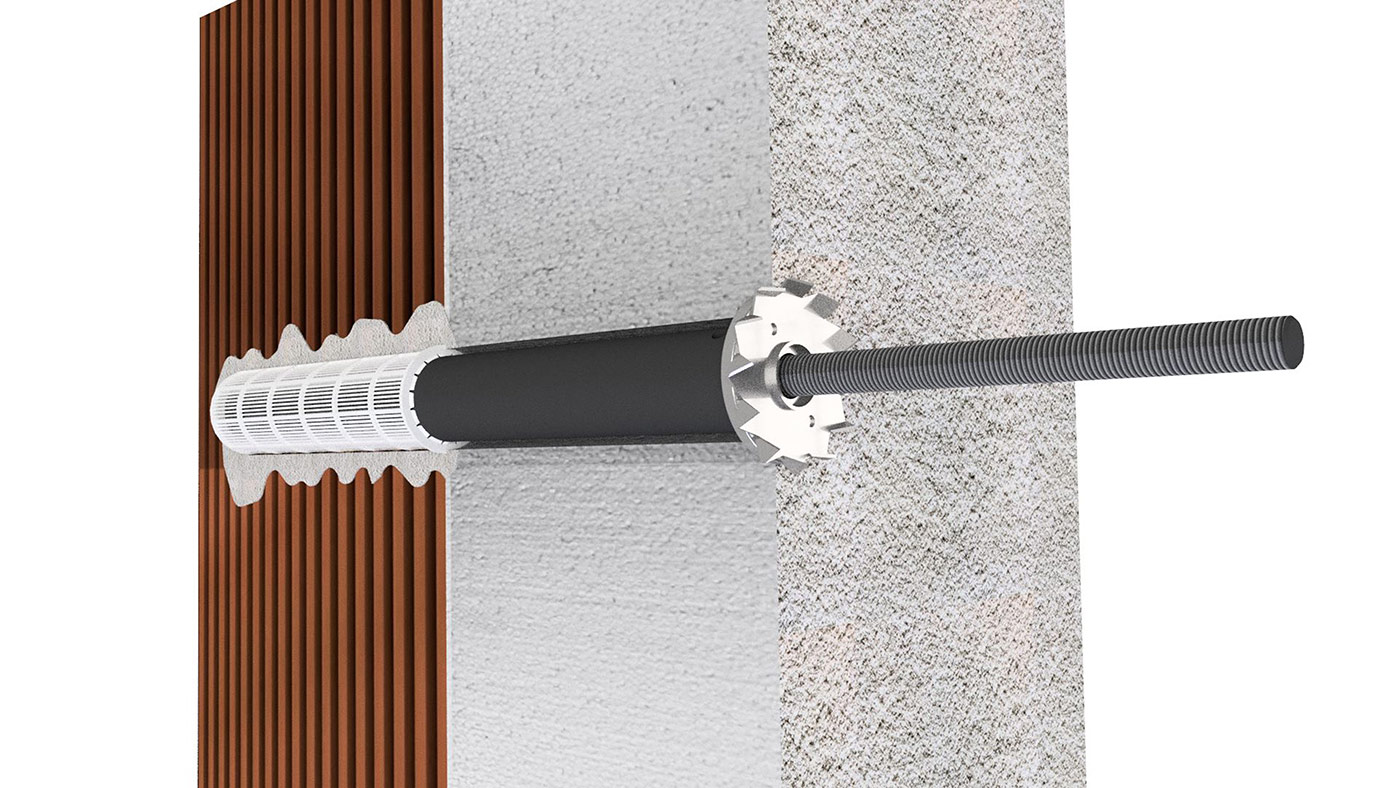

The ProziFix® is an innovative wall anchor for vertically perforated bricks that offers several advantages in timber construction. Consisting of an anchor pipe with SC9 coating, the anchor ensures high corrosion protection. SIHGA® fastening solutions also work as a system: this means that the products can be combined and complement each other perfectly. This ensures simple, safe and time-saving assembly on the construction site.

The load transfer cannot be achieved with any other commercially available system

The sealing disc re-seals the façade

SC9 coating ensures long service life

Time-saving, practical and precise

All accessories are provided

Assembly of canopies, carports and pergolas

A 50 millimetre hole in the masonry is required for the installation of the ProziFix® wall anchor. For this purpose, SIHGA® provides the special ProziFix® drill, which cuts the hole precisely and without damaging the brick. First, the screening sleeve is placed in the wall and the front section of the ProziFix® is treated with BeziFee® to create a secure connection. The ProziFix® wall connector is then inserted into the hole and fixed in place by the adhesive, which at the same time protects the vertically perforated brick from cracking. The masonry is then sealed with the sealing disc to make it driving rain-proof. Finally, the disc dowel is installed, which can provide a rear ventilation gap of between 0 and 6 mm:

- For un-roofed structures, a six millimetre gap should be left between the wall and the disc dowel to allow the wood to dry.

- This is not required for roofed constructions.

SECURELY ANCHORED WITH THE PROZIFIX®

The ProziFix® wall anchor bridges up to 200 millimetres of thermal insulation and thus saves time and material during installation. The anchor can also withstand a load of 1.80 kilonewtons – with conventional solutions, this value is only around 0.4 kilonewtons.