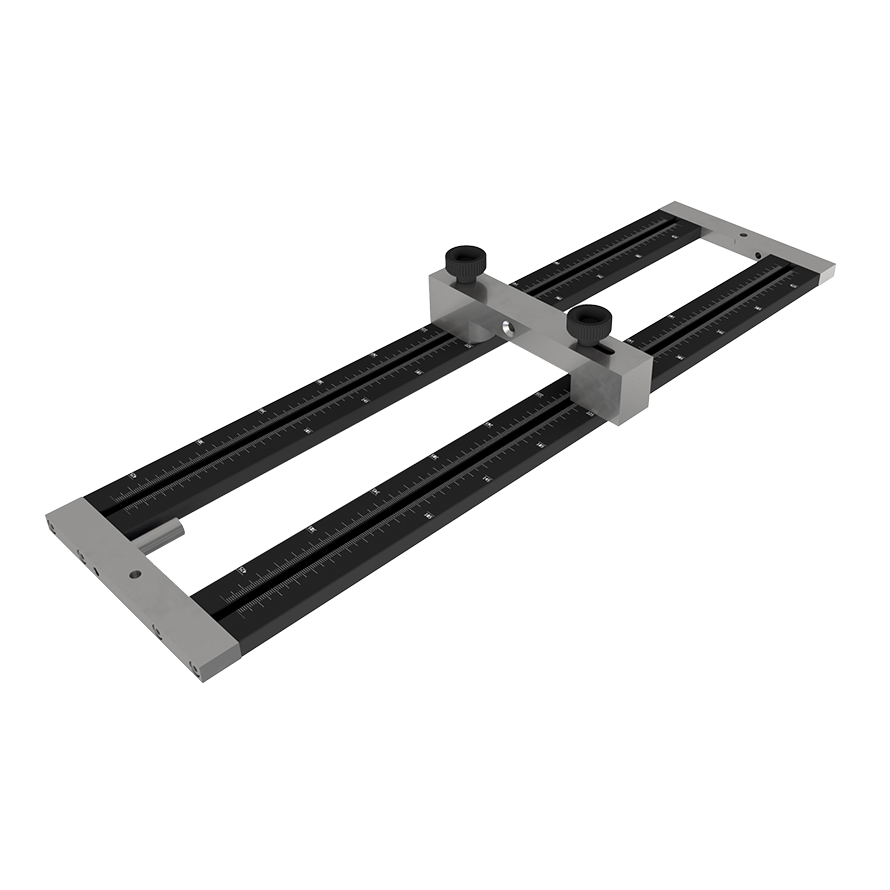

HobaFix® Max milling assembly jig

Price and ordering function are only visible after successful login.

To the login

product information

SIHGA® tip

In order to obtain a nice closed joint with the milled version, a milling depth of 15.5 mm is recommended.

From the point of view of the secondary beam, the right-hand locking screw should be screwed

in first to achieve a contraction effect. It is recommended that the first locking screw is screwed

in halfway before the second screw is fully screwed in and then the first screw is finished.

For all models of the HobaFix® Max

For the rational and precise assembly of HobaFix® Max on the main beam and on the secondary beam

For the rational and precise assembly of HobaFix® Max on the main beam and on the secondary beam

Optimal in use with HobaFix® Max milling cutter (to be purchased separately)

The HobaFix® Max can be milled in one operation thanks to the coordinated cutter length and position of the thrust ring

The HobaFix® Max can be milled in one operation thanks to the coordinated cutter length and position of the thrust ring

The jig stop can be continuously adjusted in height

and at an angle of up to 30°

Offers maximum flexibility

Offers maximum flexibility

Developed and produced in Austria

Superlative European quality and added value

Superlative European quality and added value