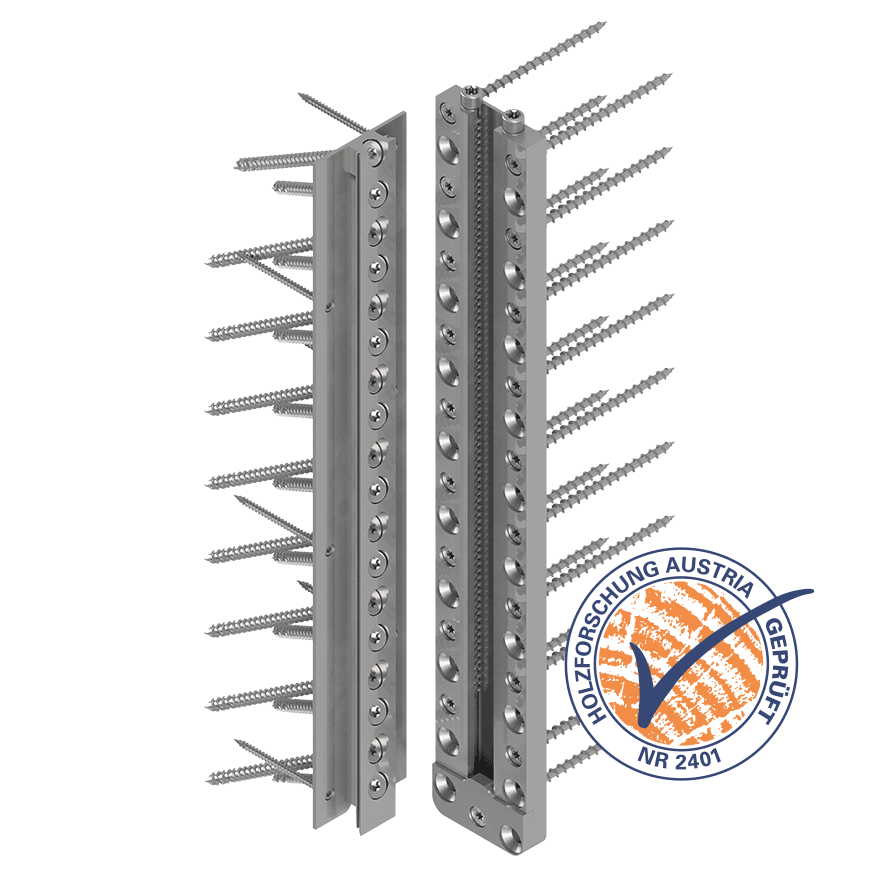

HobaFix® Max

Connectors for main beam - secondary beam constructions

Price and ordering function are only visible after successful login.

To the login

product information

SIHGA® tip

The screw connection of the two connector parts can also be made from the underside (in the case of

non- milled applications).

Connector for main beam - secondary beam

constructions

Wood-wood or wood-concrete connections are possible with the HobaFix® Max (BeziFix anchors 7.5 x 80 for concrete must be ordered separately)

Wood-wood or wood-concrete connections are possible with the HobaFix® Max (BeziFix anchors 7.5 x 80 for concrete must be ordered separately)

No screw collisions thanks to offset fastening

screws

Multiple node connections of e.g.: four beams on one support can be created

Multiple node connections of e.g.: four beams on one support can be created

With the sophisticated coupling of the connectors

by means of thread-cutting screws, several

connectors can also be mounted next to and on top

of each other

The thread-cutting locking screws distribute the load equally over the entire height of the connector and fix the position of the two beams in relation to each other at the time of bolting. This ensures an assembly tolerance in the insertion direction for multiple arrangements

The thread-cutting locking screws distribute the load equally over the entire height of the connector and fix the position of the two beams in relation to each other at the time of bolting. This ensures an assembly tolerance in the insertion direction for multiple arrangements

Flexibility in the connection mechanism

Due to the practical geometry of the connector, length tolerances of the secondary beam of up to -3 mm can be accommodated (with connector arrangement on both sides)

Due to the practical geometry of the connector, length tolerances of the secondary beam of up to -3 mm can be accommodated (with connector arrangement on both sides)

High static load capacity in six load cases, with up

to 81,73 kN being characteristic per connection

Can be used for horizontal, vertical, tensile and torque loads with high tested static values

Can be used for horizontal, vertical, tensile and torque loads with high tested static values

Excellent price-performance ratio

Thanks to the consistent profile geometry across all connector heights, an optimised manufacturing process helps save time and money

Thanks to the consistent profile geometry across all connector heights, an optimised manufacturing process helps save time and money

The different HobaFix® Max differ only in length and

the number of screws

All connector sizes can be mounted with just one template

All connector sizes can be mounted with just one template

Developed, patented and manufactured in Austria

Highest European quality and added value

Highest European quality and added value

Made under supervised conditions from aluminium

and anodised

Durable, dimensionally stable quality

Durable, dimensionally stable quality

Includes SIHGAFIX®, all fastening and fixing

screws, assembly instructions

Time-saving, practical, precise; all accessories are included

Time-saving, practical, precise; all accessories are included