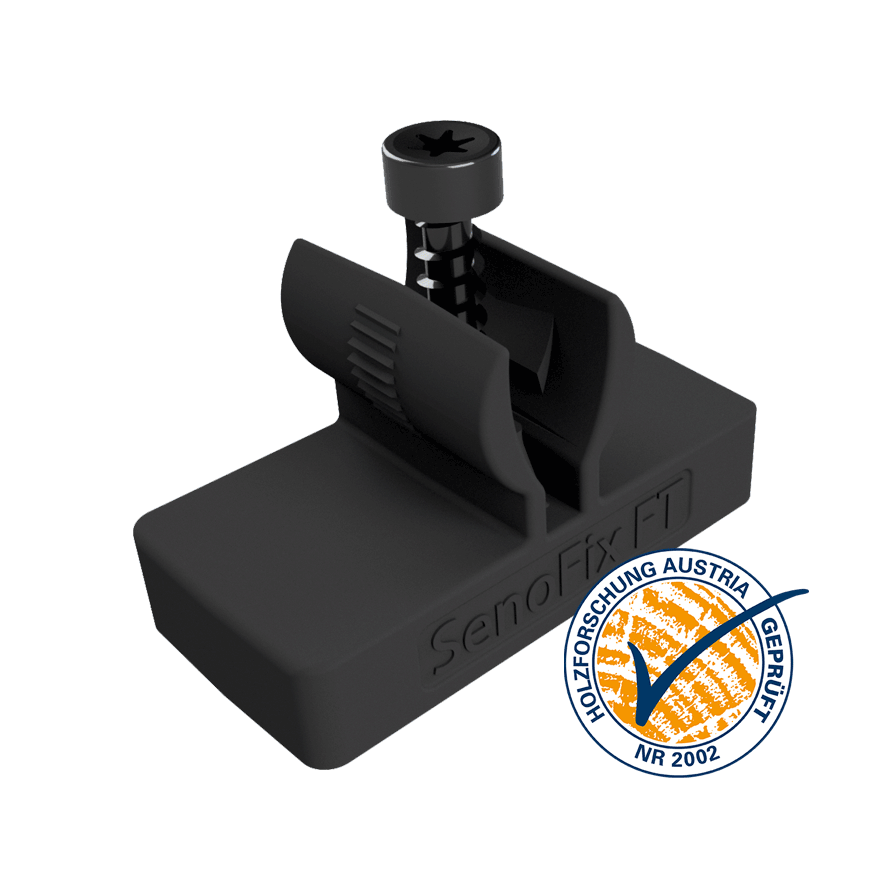

SenoFix® FT

für Terrassen- und Fassadenanwendungen

Preis und Bestellfunktion sind erst nach erfolgreichem Login sichtbar.

Zum Login

Produktinfo

SIHGA® Tipp

Konstruktionsempfehlungen beachten.

Für geölte Terrassen empfehlen wir den SenoFix® II SX. Sichern Sie jede Fassadendiele einmal mit BohrFix® FB 4,2 x 43.

für naturbelassene, von SIHGA® freigegebene,

profilierte Hölzer

als Unterkonstruktion ist die TefaFix® T optimal

als Unterkonstruktion ist die TefaFix® T optimal

Anwendung durch zusätzliche Sicherungsschraube

bei vertikalen Fassadenbekleidungen

Sicherheit gegen ein Abgleiten der Fassadenprofile

Sicherheit gegen ein Abgleiten der Fassadenprofile

in Österreich entwickelt, patentiert und hergestellt

höchste europäische Qualität und Wertschöpfung

höchste europäische Qualität und Wertschöpfung

nur in der Fuge durch den SenoFix® FT geschraubte

Dielenbefestigung, Deck- und Seitenflächen der

Dielen bleiben unverletzt

einfach, präzise und schnell entsteht die optisch anspruchsvolle Oberfläche

einfach, präzise und schnell entsteht die optisch anspruchsvolle Oberfläche

NUR für von SIHGA® freigegebene, profilierte

Hölzer

höchste Sicherheit durch Langzeittests

höchste Sicherheit durch Langzeittests

Spreizmechanismus mit Fugenbreite von 7 mm im

Endzustand

keine Distanzhalter zur Montage nötig

keine Distanzhalter zur Montage nötig

Montage ohne zusätzliche Werkzeuge möglich

keine zusätzlichen Kosten für Zwingen oder Gurte usw.

keine zusätzlichen Kosten für Zwingen oder Gurte usw.

Verbinderhöhe nach neuestem Stand der Technik

automatische Distanz zur Unterkonstruktion von 8 mm

automatische Distanz zur Unterkonstruktion von 8 mm

stabilisiert und kompensiert Quell- und

Schwindvorgänge des Holzes

erhöht die Lebensdauer der Terrasse wesentlich

erhöht die Lebensdauer der Terrasse wesentlich

nur 1 Schraube pro Befestigungspunkt

spart 50 % der Montagezeit und gibt perfekten Halt

spart 50 % der Montagezeit und gibt perfekten Halt

erhältlich mit 2 verschiedenen Schraubenlängen

Anwendung auf Holz- und Alu-Unterkonstruktion

Anwendung auf Holz- und Alu-Unterkonstruktion

aus verstärktem SIHGAMID® hergestellt

ist somit dauerhaft hitze-, frost- und UV-beständig

ist somit dauerhaft hitze-, frost- und UV-beständig

Befestigungsschraube aus gehärtetem, rostfreiem

Edelstahl hergestellt

ist dauerhaft und bruchfest

ist dauerhaft und bruchfest

inkl. SIHGAFIX® Edelstahl rostfrei, allen

Befestigungsschrauben und Montageanleitung

zeitsparend, praktisch, präzise; gesamtes Zubehör ist beigepackt; SIHGAFIX® Edelstahl rostfrei verhindert Fremdrost

zeitsparend, praktisch, präzise; gesamtes Zubehör ist beigepackt; SIHGAFIX® Edelstahl rostfrei verhindert Fremdrost

Mengenermittlung pro m²

1 : Abstand Unterkonstruktion [m] : (Breite Diele [m] + Fuge [m])

1 : Abstand Unterkonstruktion [m] : (Breite Diele [m] + Fuge [m])

HFA-geprüft in Kombination mit Thermoesche

Mit dem TerrassenFix® Tiefenbegrenzer TTB wird ein zu tiefes Eindrehen der Schraube verhindert.

Zum Video